SoliPaper

The SoliPaper product range consists of uniform, lightweight, low shot and flexible paper-like products. SoliPaper is very flexible, but offers a high tensile strength and resiliency thanks to the high fiber index.

SoliPaper is particulary suited to all applications requiring further processing (laminated composites, die-cutting, rolling, folding) and can easily be converted to gaskets in domestic boilers. Let’s first highlight some of the most common applications for our SoliPaper product range:

- Filler for expansion joints between pre-casted shapes and IFB linings

- Die cut gasket for domestic appliances, like boilers and heaters

- Thermal insulation in automotive heat shields

- Flexible gasket in fireprotection for windows and doors.

- Parting medium in brazing and soldering

- Non-ferrous molten metal handling or back up lining for ladles

- General technical insulation solution.

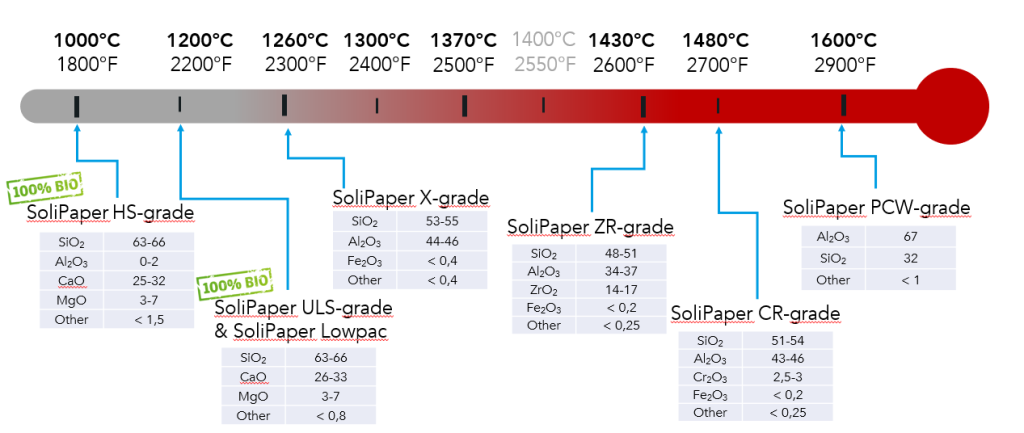

SoliPaper is available in both Refractory Ceramic Fiber (RCF), Low Bio Persistence (LBP) and Polycrystalline Wool (PCW) fibers. Thanks to our wide selection of chemical compositions the Solipaper products are offered in a range covering a classification temperature from 1200 till 1600°C (2200 till 2900°F). Together with our wet laid felts based on E-glass and Silica, used in intermediate temperatures from 250 till 900°C (500 till 1650°F), we are offering one of the widest ranges of high temperature and fire protection paper products.

The top of our SoliPaper product range is the SoliPaper PCW which is based on an unique chemical composition which consists of approximately 80% Mullite fiber and 20 % of our SoliWool HA fiber. The result is an excellent strong high temperature paper with a classification temperature of 1600°C (2900°F).

For die-cut gasket cutting the most popular product is our SoliPaper ULS, and as a recent addition the industrial grade version: Solipaper ULS ‘LOWPAC’. Compared to standard high paper products the LOWPAC is still outperforming most competitors, ensuring mechanical sealing and good air tightness.

SoliPaper is manufactured on our own developed continuous paper line which is has some very clever engineering features. These clever details are ensuring the high quality level of our paper products.

For example; We manage the thickness and density of our paper products using X-ray. This does not only help us to ensure the highest quality, but also allows us to manufacture paper as thin as 0,8 mm (1/32 inch) at full customer satisfaction.

All our SoliPaper products are based on our own Generation III SoliBulk , which secures a premium quality as result of our high fiber index and very low shot contents. Actually, the SoliPaper has been so well received that we have commissioned our 2nd paper line from summer 2021.

SoliPaper is available in 7 grades and 6 chemical compositions which all function till another classification temperature, or are designed for specific atmospheres and applications. Of these 6 chemical composition, 3 are completely unique from any other potential alternative. Our ambition is to keep innovating the range of high temperature fiber papers to ensure we are there to support your needs.

The latest addition is the SoliPaper High Strength (HS) grade, which is manufactured from our 1200°C rated Low Bio Persistence fiber; SoliWool ULS, and special high strength fibers to create a paper which is up till 8 times stronger than ‘standard’ paper. The SoliPaper HS is recommended for the production of gaskets or for self adhesive paper strips in windowframe applications.

The Standard Grade RCF range SoliPaper consists of 2 types of Refractory Ceramic Fiber paper for the temperature range of 1260°C to 1430°C : the X-grade and the ZR-grade.

Special Grade SoliPaper consists of 2 types of paper including a Chrome grade, the SoliPaper CR and the earlier mentioned SoliPaper PCW which is manufactured from approximately 80% Mullite fiber and 20 % of our SoliWool HA fiber. Both of these products are designed to perform at the highest temperature range and can be used in demanding atmospheres.

As third group we have the low bio persistence SoliPaper which is labelled our ‘ULS®’ grade. We offer the SoliPaper ULS in 2 grades; SoliPaper ULS and SoliPaper LOWPAC. SoliPaper ULS is our standard low bio persistence fiber paper which is offered in both standard and jumbo rolls. For high volume gasket manufacturing we offer the SoliPaper LOWPAC which could be considered our industrial grade and is manufactured with a lower density and tighter thickness specification.

All products in the SoliWool ULS fiber product range, like the SoliPaper ULS, meet the requirements specified under NOTE Q of European Regulation 1272/2008. All SoliPaper ULS products are therefore exonerated from labelling requirements in Europe.

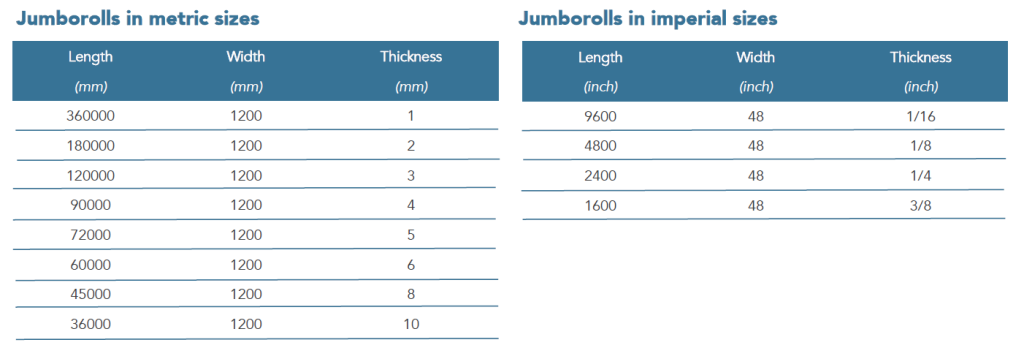

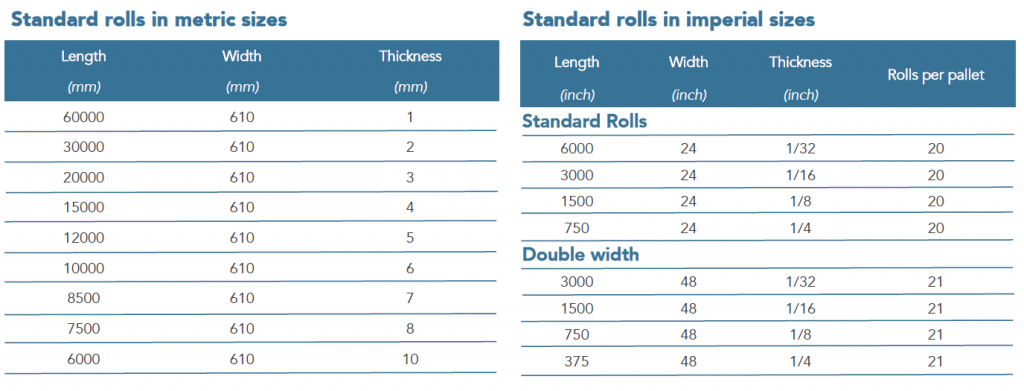

All the SoliPaper products are available in a thickness range from 1 to 10 mm in Europe and 1/32 till 1/4 of an inch for America. For more details about our product size and packaging per pallet we refer to the lists below.

We offer our SoliPaper in both standard and jumbo rolls (with exclusion of SoliPaper PCW which is only available in standard rolls).

The jumborolls have a standard width of 1200 mm which allow them to be loaded with 4 rolls per pallet. The jumborolls are provided with heist belts in the roll which allow swift loading on the feeder for high volume gasket cutting.

Standard rolls are provided in carton boxes with a standard width of 610 mm (24 inch) or in double width of 1220 mm (48 inch).