Welcome to Vulcor Insulation

Introducing revolutionary insulation solutions for the industry

Introducing revolutionary insulation solutions for the industry

Vulcor Insulation differentiates itself through its unique Generation III, Ultra Low Shot fiber products, delivering outstanding thermal performance, superior tensile strength, and smoother handling. Our solutions are engineered for durability in harsh industrial environments, operating at temperatures from 700°C up to 1650°C.

Headquartered in the Netherlands, Vulcor Insulation operates sales offices in North America (USA), the Turan and Middle East region (Turkey), and Central & Eastern Europe (Hungary), supported by a global network of distribution partners and installers. With large manufacturing capabilities in Turkey and China, Vulcor manages the development, certification, technical support, logistics, and global distribution of SoliWool™ fiber-based insulation solutions.

Serving a wide range of industrial markets and applications, Vulcor delivers advanced, energy-saving insulation technologies worldwide by combining global reach with local expertise. Vulcor Insulation helps you save energy; efficiently, reliably, and sustainably.

SoliWool High Temperature

SoliWool High TemperatureThe heart and soul of Vulcor Insulation. SoliWool product range is one of the most extensive fiber ranges on the market. Targeted to provide the best possible thermal insulation solution for use in high temperature applications. We offer multiple Refractory Ceramic Fiber chemistry compositions, a range of Low Bio Persistence Fibers and a range of converted products based on Poly Crystalline Wool up to 1650°C

Revolutionary Hybrid System

Revolutionary Hybrid SystemOur Hybrid System combines the best of both worlds: the robust, non-respirable properties of Poly Crystalline Wool (PCW) on the hot face, and the safe, Low Bio Persistence (LBP) fibers on the cold face. The microporous interlayer optimally reduces heat transfer, ensuring that the LBP side remains below 1050 °C, keeping it safe from forming Respirable Crystalline Silica (RCS).

SoliBoard Productrange

SoliBoard ProductrangeWe are the leading manufacturer of high temperature board products which can be used in many applications varying from backup behind a dense or insulating lining, in the heat exchanger of a domestic boiler or for high temperature applications in ceramic kiln. Our state-of-the-art drying techniques reduced energy consumption by 70% and allow us to manufacture a uniform, lightweight, low shot and stable board to a thickness of 100 mm.

Vulcor Insulation is bringing you the latest generation high temperature fiber products.

If you were to see the factory where we manufacture our SoliWool™ fiber solutions, it is hard to imagine that back in 2017 it was just a ‘Greenfield’ plan. Today our state of the art factory spans 75.000 m2 (800.000 ft2) and manufactures the most advanced high temperature fibers products.

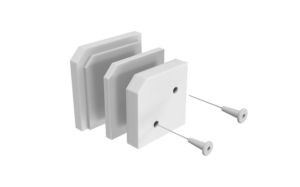

The SoliWool™ product range consists of engineered bulk fiber, Ultra Low Shot technology blankets, dust free and smooth papers, flexible felts, high tech manufactured board products, tailored to shape vacuum formed shapes and one of the widest ranges of fiber modules.

All the SoliWool™ are manufactured with our Generation III, Ultra Low Shot technology. SoliWool™ is outperforming conventional refractory ceramic fibers (RCF) and low bio persistence fibers (LBP) on thermal conductivity, mechanical strength and handling.