Awareness on shot contents

Refractory Ceramic Fibers have been around since the 1960’s. By 1990 the first Low Bio Persistence fiber was introduced and have grown strongly since due to obvious health and safety benefits.

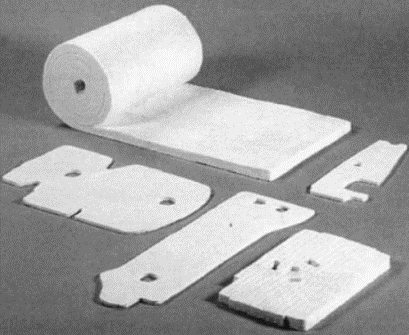

High temperature fiber products, like our SoliWool product range, have been the preferred choice of insulation in many high temperature applications. The reasons are simple: it is durable, low weight (and as a result accumulate little energy), has good thermal shock resistance, and most importantly, offer excellent thermal insulation performance.

However, there is a problem… Not all fiber products are equal in performance and the key word, explaining the difference, is ‘fiber index’.

Fiber index is the percentage of good fibers in

percentage to the shot content.

Shot can be defined as small granular glass which is formed during production, and thus did not convert to a fiber material. When manufacturing high temperature fiber from a melt process (spun or blown), shot is an inevitable byproduct to the desired fiber.

Shot particles do not contribute to a better thermal insulation of the product, nor enhance the mechanical properties of the fiber product. Realistically the only thing ‘shot’ adds, is weight to your fiber based product.

So, logically the next step made by the traditonal leading manufacturers of fiber products was focussing on the reduction of the shot contents. This awareness on the effect of the shot contents led to the development of low shot fiber products, or Generation II fiber technology. We are proud to offer all our SoliWool products based on our Generation III, or Ultra Low Shot fiber technology.

Generation III fiber

As asset owner your main interest is a long lifetime of your refractory lining. At Vulcor Insulation we are providing much more than that… Better thermal insulation means lower CO2 emissions, lower gas consumption and safer casing temperatures. And this is all relating to the Generation III or Ultra Low Shot (ULS) technology, which the basis of every fiber solution we are providing to the market.

Compared to a Generation I or Generation II high temperature fiber the SoliWool product range is providing a better thermal insulation, a higher mechanical strength and an improved handling. These improved technical properties are the result of our low shot contents compared to the other types of insulation fiber.

We are proud to be the first supplier to offer you Generation III fiber products as a standard. This will allow you to deliver better insulated systems, providing better workmanship and keeping your workers (handling the product) safe and happy.

Innovation

At our manufacturing facility we have an extensive laboratory which is not only involved in the daily quality control and quality assurance (ISO 9001), but also is responsible for the development of new products and production technologies.

The development of new products is done in close cooperation with the technical team of Vulcor Insulation in the Netherlands. Doing so, we have a phenomonal trackrecord of bringing new products to market. Even though we still consider ourselves ‘the new kid on the block’, we already offer an extensive range of product unlike many other companies.

Vulcor Insulation moves in lightspeed pace…

In an industry which practically has been the same for over 20 years we have been moving forward with the implementation of new technologies and products. Since our start we have brought you:

- Unique Generation III fiber technology resulting in better insulation and strength,

- High Strength paper which was developed for the automotive, but gets lift off in fire protection,

- Monolitic Fiber Modules offering an alternative to standard stack and/or folded fiber modules,

- Spun High Alumina 1370°C RCF delivering better chemical resistance to alkali and fluxing agents as RCF-Zr blankets,

- and PCW/RCF blended boards and papers for temperatures between 1500°C till 1650°C. Giving you the benefit of the higher temperature use, without the high costs of full PCW based products.