Generation III technology leads to Ultra Low Shot blanket

Thank you for taking a moment to learn more about our SoliBlanket product range. As fiber blankets have been the backbone for high temperature insulation industry, it is important to understand what sets us apart from other manufacturers in this industry.

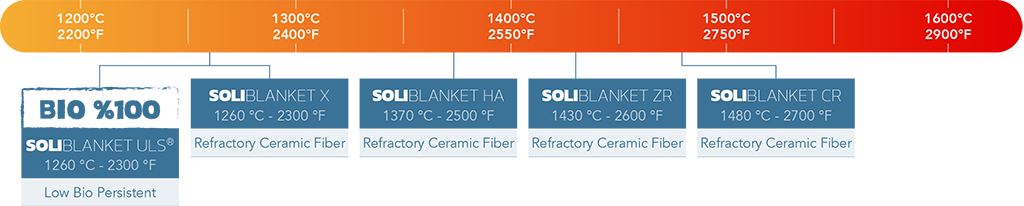

The SoliBlanket product range is consisting out of a variety of five Refractory Ceramic Fiber (RCF) grades and the famous ‘ULS®’ Low Bio Persistence Fiber grade. In summary we are offering one of the most extensive ranges of high temperature fiber blankets in the market today. With our different chemical compositions we are able to provide a solution to nearly every atmosphere or temperature.

SoliBlanket is typically used for the following applications:

- Thermal insulation for furnace lining

- Thermal protection cover in aluminum industry

- HRSG thermal liner for boilers and ducting

- Exhaust heat shields for automotive application

- General technical insulation of furnaces and technical installations

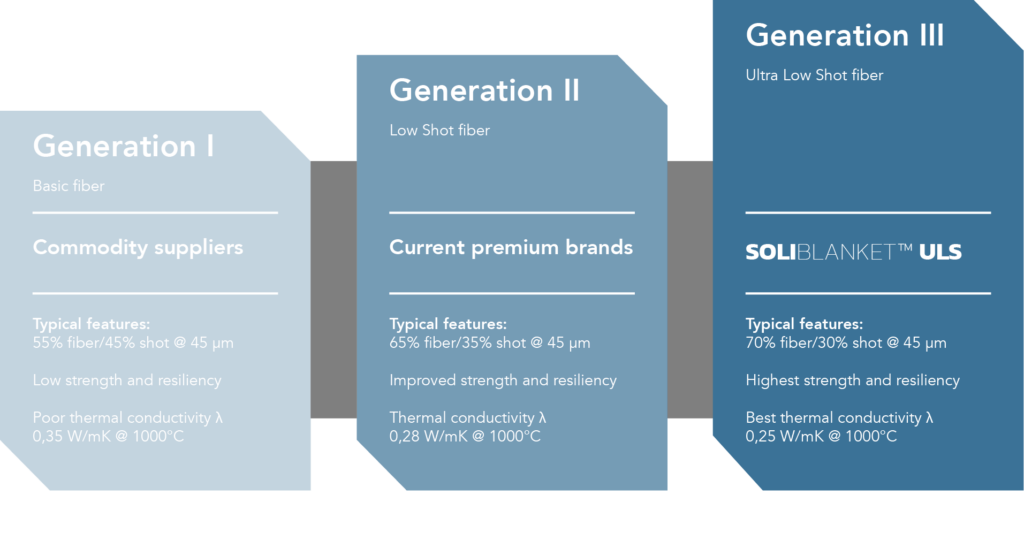

For several decades Refractory Ceramic Fiber and Low Bio Persistence blankets have been manufactured in a more or less similar method. When we built our factory back in 2018 we had a strong ambition to deliver a new generation of insulation fiber. A product range which would be unique to the standard product offering of our competition.

Soliblanket is the first full range of Generation III, Ultra Low Shot fiber blankets, which are targeted to deliver better thermal performance and higher strength, resiliency and handling characteristics. The key to these improved properties start with the production process. Optimized to minimize shot contents, and in result, increased the fiber index.

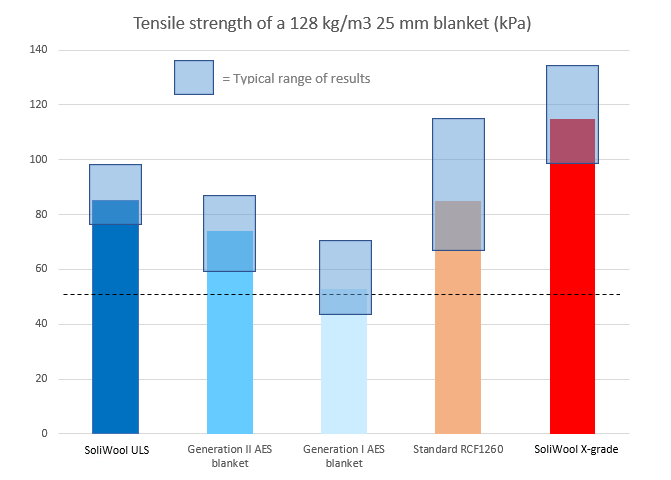

The better thermal performance is not the only benefit of the Generation III fiber technology. Our SoliBlanket is offering higher strenght and a smoother handling. Compared to Generation I and Generation II fiber blankets the SoliBlanket is offering a higher tensile strength, and this benefit is not only applicable on low bio persistence fibers, but on all our SoliBlanket products.

In the past the general consensus was that a Refractory Ceramic Fiber was stronger than the equivalent Low Bio Persistence fiber at the same density. With the Generation III fiber technology this is no longer the case.

When converted into fiber modules the SoliBlanket products are offering a higher resistence and resiliency afther compression. As a result a fiber module manufactured from SoliBlanket strips are not only offering better thermal insulation, but also offer higher strength and a tighter installation.

As the SoliBlanket products have a better needling the surface is smoother, less dusty and offer a higher resistence to high gas velocities. We believe that all together SoliBlanket is more durable and results in a longer lifetime of the refractory lining.

The SoliBlanket product range is consisting out of a variety of five Refractory Ceramic Fiber (RCF) grades and currently one Low Bio Persistence (LBP) Fiber grade. Our five SoliBlanket RCF grades all function till another classification temperature, but the difference go much further than that. All the different SoliBlanket RCF grades have specific applications and atmospheres where they perform strongest.

Where a standard X-grade or ZR-grade blanket is mainly used as a general purpose blanket, the HP-grade, HA-grade and the CR-grade are developed to work in very specific applications. For this reason we split this offering in 3 sub groups: Standard Grade RCF, Special Grade RCF and the Low Bio Persistence blankets

The Standard Grade RCF range SoliBlanket consists of 2 types of Refractory Ceramic Fiber blankets for the temperature range of 2300°F to 2600°F: the X-grade and the ZR-grade.

The Special Grade RCF range SoliBlanket consists of 3 types of Refractory Ceramic Fiber blankets including a High Purity grade, the SoliBlanket HP, a unique spun High Alumina blanket, SoliBlanket HA, and a Chrome blanket, the SoliBlanket CR. A special notice to the SoliBlanket HA which is unlike all other RCF blankets; a 1370 °C rated fiber, made without zirconia.

As third group we have the low bio persistence SoliBlanket which is labelled our ‘ULS®’ grade. SoliBlanket ULS is the first commercially offered Generation III, Ultra Low Shot, fiber blanket which is offering superior handling, toughest strength, and optimized thermal insulation.

The Ultra Low Shot Fiber technology, which is shared among the all the SoliBlanket products, is making the difference between ‘good enough’ and ‘best of class’. This translates into 3 main benefits:

- Superior handling

- Toughest tensile strength

- Lowest thermal conductivity

And as we believe that reducing energy consumption and minimizing CO2 emissions will become part of sustainable environmental drivers, optimizing the thermal performance of the refractory lining will become more important.

As a result of the high fiber from the Ultra Low Shot technology independent testing has shown that SoliBlanket X grade is outperforming any of the other tested RCF blankets with test results up to 36 % better. If you are looking for the best thermal performance and durability of your fiber lining, please make sure to use Generation III fiber products.

We have listened to our customers and in main complaint is the unpractical size of the carton boxes. For that reason SoliBlanket is typically supplied in tight shrinkwrap packaging and palletized with 24 rolls per pallet.

We have chosen for this new type of packaging as traditional carton boxes are not offering the same level of protection to weather influence when product temporary needs to be stored outside. Of course, for long term storage, dry storage is required, but on the jobsite this can not always be avoided.

A second reason to select this new type of packaging is easier handling and less waste. When maneuvering the product into the furnace there is always some manual internal transport involved. The general feedback is that our new packaging is more practical to feed through the manhole and is more convenient when carried. As we are keen to make our contribution to the environment, and that plastic packaging is not environmentally friendly, the ecological impact of the packaging is compensated.

SoliBlanket products are available in a wide range of dimensions and densities from

4 to 10 PCF and thicknesses from 1/4 tot 2 inches. The typical width of the blankets is 24 inches, but we also offer the SoliBlanket in 48 inches width.