It’s as easy as 1-2-3…

We are proud to introduce the first Generation III, Ultra Low Shot fiber in the world. Not as a premium, or only available in a limited productrange, but available in all our Refractory Ceramic Fiber and Low Bio persistence fiber grades. In result, you are getting the best thermal insulation, toughest strength and smoothest handling.

The introduction of the Generation III, Ultra Low Shot technology has proven to be a game changer to those who have been working with the product. ULS technology is delivering you the difference between ‘fit for purpose’ and ‘best in class’.

Smoother and stronger blankets, higher yield of bulk fiber in vacuum forming processes, better machinability on boards, higher resiliency after compression of fiber modules and cleaner cut gaskets from our papers and felts. The key to these improvements is the higher fiber index and lower shot contents. Let us explain what makes us so enthousiastic about Ultra Low Shot technology fibers…

Thermal insulation restricts the flow of energy with respect to:

· Thermal radiation

· Thermal conduction

· Thermal convection

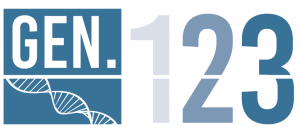

For high temperature insulation thermal radiation is the dominant form of energy transfer above 400°C and even more applicable for low density high temperature fiber products.

Fiber structures block radiation by having a large number of surfaces. As the radiation interacts with each surface, which becomes hot and will re-emit radiation (at a lower intensity) in all directions, and so transfer through the fiber structure is restricted.

For this reason the high fiber index, which also results in more surface area to interact with thermal radiation, is not only important from a strength or handling perspective, but it also delivers better thermal insulating properties.

Independently tested the SoliBlanket ULS-grade outperforms the ‘best in class’ Generation I and Generation II fiber products with up to 30% improvement on thermal conductivity.

For SoliBlanket X-grade (refractory ceramic fiber), compared to its ‘peers’, the difference in measured thermal conductivity, is up to 42% in favour of our Ultra Low Shot technology.

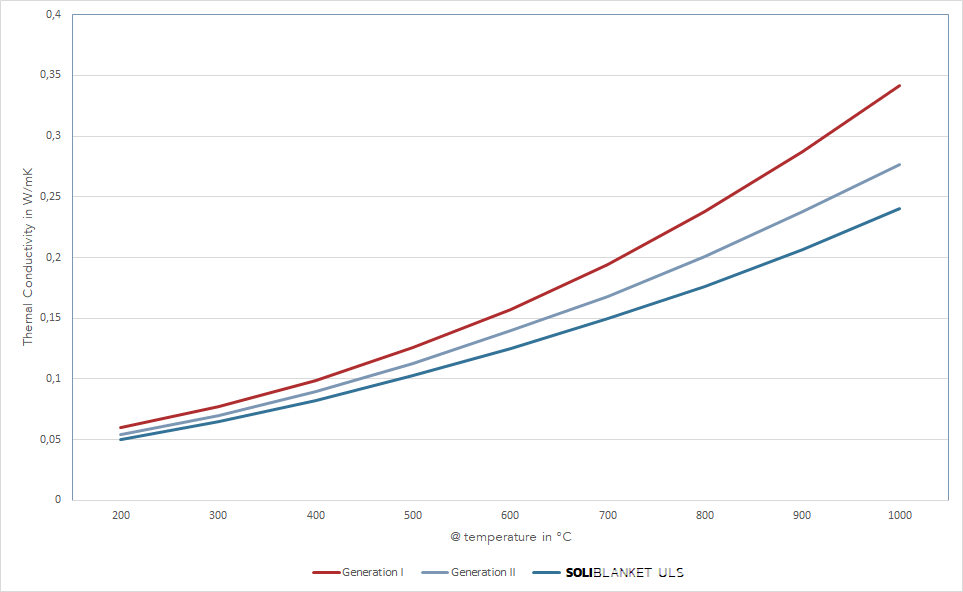

High temperature fiber blankets are ‘needled’ to convert from a fleece to a blanket. During the needling process, interlocking for the fibers in the fiberstructure is achieved. High fiber index and advanced needling technology are crucial to achieve the toughest tensile strength.

In addition to tensile strength, delamination strength, and resiliency are improved. All together, even thou these other properties are not typically mentioned on a datasheet could be considered the mechnical strength of a blanket.

Why is high mechnical strength relevant?

Not only does it affect the handling, but higher mechanical strength also means that the product can withstand higher gas velocities, both parallel and perpendicular to the dominant fiber

orientation.

But the most relevant strength features next to the tensile strength, is the resiliency of the blanket. The resiliency is the % of ‘spring back’ in a relax state after compression perpendicular to the main fiber orientation.

Internal testing confirm that the pre-load to achieve 50% thickness compression for our Ultra Low Shot, Generation III blankets is up to 42% higher, but even then the resiliency, or spring-back remains 18% higher compared to Generation I blankets.

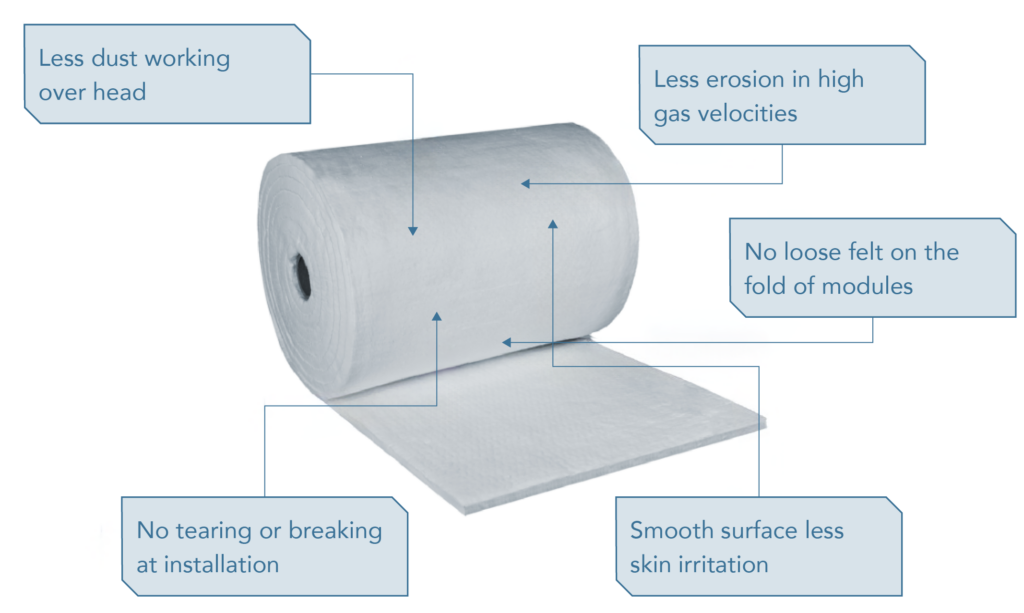

The last feature resulting from the Ultra Low Shot technology is the least easy to quantify in numbers..

How do you define less fiber dust working over head installing the product in the roof of a furnace?? Be assured you the installation team installing the blankets can tell you the difference.

Better interlocking of fibers, higher fiber index, lower shot content, all result in superior handling of the blanket we are supplying to the market.

- Less dust working over head (roof of furnace)

- No tearing or breaking of the blanket during installation (which is typically the case with thin blankets and low density products)

- No soft spots and even thickness distribution over the width of the blanket.

- Smooth surface resulting in less skin irritation

- No loose felt on the folds of blanket strips or modules

The ULS technology means better fiber, higher fiber index, advanced needling, less dust from the product, and in result less skin irritation and better handling.

Vulcor Insulation is innovating the market

We might have introduced ourselves as the New Kid in town, but our team has been in the industry for many years. We have been making industrial insulation solutions for many years, but why having thoughts on how to make good products even better and not acting? This has been the main reason to start our journey.

Now we are offering a full product range of high temperature insulation products, and the stars of our range are the SoliWool products. To explain how innovative these products are, we would like to introduce you to this little timeline for high temperature fiber products.