Ultra Low Shot Technology

As Vulcor we are proud to introduce the first Generation III, Ultra Low Shot fiber in the world. Not as a premium, or only available in a limited productrange, but available in both our Refractory Ceramic Fiber and Low Bio persistence fiber grades. The introduction of the Generation III, Ultra Low Shot technology has proven to be a game changers to those who have been working with the product. Smoother and stronger blankets, higher yield of bulk fiber in vacuum forming processes, better machinability on boards, higher resiliency after compression of fiber modules and cleaner cut gaskets from our papers and felts. The key to these improvements is the higher fiber index and lower shot contents.

It is as easy as 1-2-3…

Vulcor is proud to present you the innovation of ULS technology. ULS technology is the next generation of high temperature fiber materials maximizing the fiber index and minimizing the shot contents. If you are looking for the highest thermal performance the industry has to offer with superior handling and highest mechanical strength than our ULS technology fiber products are what you need for your next insulation project. Whilst ULS technology is delivering you the difference between ‘fit for purpose’ and ‘best in class’. You can also expect long lifetime of the refractory lining, vibration resistance and minimum shrinkage at the maximum continuous use temperature. Let’s take a look at what makes us so passionate about the ULS technology…

Ultra Low Shot Technology

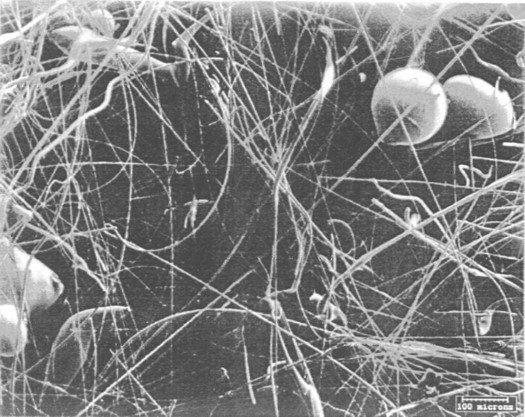

High temperature fibers, both Refractory Ceramic Fibers and Low Bio Persistence fibers (also referred to as AES fibers) have been the product of choice for many high temperature applications over the last few decades. And all these fiber products consisted up to 50% of their weight in ‘shot’. Shot can be defined as small granulair glass which is formed during production, and thus did not convert to a fiberous material. These shot particles do not contribute to a better thermal insulation of the product, neither do shot particles help the mechanical properties of the blanket… Realistically the only thing ‘shot’ adds, is weight to the bulk, blanket, module, paper, board or felt product (and in application potential problems). The first low shot fiber (also referred to as Generation II fiber) product was launched in 2005 which made a massive leap foward on quality and performance of high temperature fiber products. The Generation II already delivered a part of the advantages of our ULS technology when compared to the standard fiber products.

Best Thermal Performance

The heatflow in a refractory lining is based on the performance of the insulation materials. For lightweight fiberous products at high temperature (> 600°C) the thermal radiation is the most dominate form of energy transfer. Fiberous products block radiation by having a large number of surfaces which scatter the incoming light. As the radiation interacts with each surface, its intensity is reduced and so transfer through the fiber structure is restricted. By a unique fiberisation process in our SoliWool productrange we improved the conversion from molten glass to fiber, thus optimizing the ratio of shot to fiber and minimising the size of the pieces of shot. This enhances the thermal conductivity of our SoliWool up to 30 %. The key word is the fiber index. The higher the fiber index the better the high temperature fiber will perform during its lifetime. Key factors to improve the fibre index are minimizing the shot contents and optimizing fiber diameter, the remainder is related to the fiber orientation as result of the needling system. Our SoliWool ULS technology combines all these key factors and as a result delivers you the best thermal insulation properties in high temperature fiber products. You can optimize your lining thickness or utilizes the ULS technology to reduce your energy consumption as well as your CO2 emissions.

Highest Mechanical Strength

The superior fiber index and the needling technique give the ULS technology fiber products a superior mechanical strength. But how does mechnical strength of your fiber product help you with your furnace? Higher mechanical strength means that the product can withstand a higher gas velocity both parallel and perpendicular to the main fiber orientation. At installation it also offers a better tensile strength, but most importantly the resiliency of the Generation III fiber after compression is much higher. Comparing the tensile strength of the various generation blankets on all chemistries it can be stated that the Generation III fiber is providing the highest strength. It means no tearing of blankets and no sagging of fiber blanket on studs over time.

Especially in module making the resiliency perpendicular to the main fiber orientation is very important for the strength of the module and the required compression required to make a tight and compacted fiber lining. Our Generation III, ULS, technology is providing 20% more resiliency after compression.

Superior Handling

When installing fiber materials in a furnace the worst can be working with fiber which delaminates, tears or gives loads of dust. Especially when working on the roof of furnace and the dust is settling on your face, or even worse, gets into your eyes. At Vulcor we would always advise you to wear personal protection equipment (PPE) when working with fiberous materials, but this does not take away that airborne fibers will always find unprotected pieces of skin… However these common problems are typicall the case with poor needled fibers products. The interlocking of the fibers from needling is highly increased by the fiberindex as a result of the ULS technology. Secondly, the diameter of the fibers as manufactured are linked to the potential skin irritation. Coarse fibers of 5-7 micron diameter are thick enough to penetrate the first layer of the skin and when touched or rubbed give that sting… The ULS technology means finer fibers, better needling, less dust from the product, and in result less skin irritation.