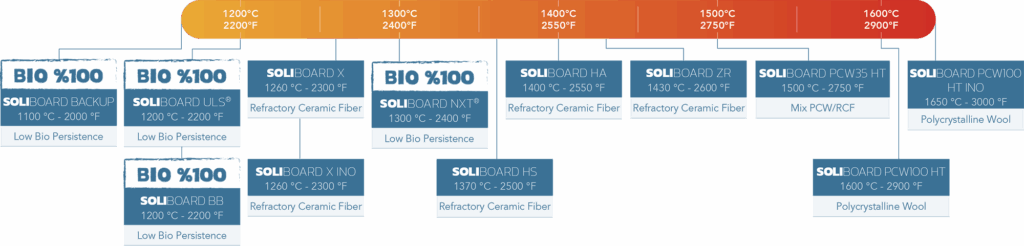

Vulcor is offering one of the most extensive product ranges in high temperature board products. We offer a complete series of standard boards, a high strength series which is both offering higher green strength as better strengh after first firing, and a special series which are manufactured from mixed fiber chemistries (typically using very high temperature resistant PCW fibers) for the most demanding applications.

SoliBoard can be used in a wide range of applications and is known for excellent machining results. Let’s first highlight some of the most common applications for our SoliBoard product range:

Thermal insulation for furnace linings

Chemical resistant lining in furnaces operating in reducing atmospheres

High temperature back-up insulation

Lining combustion chamber for domestic boilers and heaters

General technical insulation of furnaces and technical installations

SoliBoard is manufactured on our unique continuous production process. You are reading this correctly; our board is not manufactured in a batch vacuum forming method, but on a state of the art, high output, continuous board line.

Our production line has a total length of approximately 900 feet and a production width of 47 1/4 inch and is fully PLC controlled. This allows us to not only secure the highest quality, but also to be competitive at high output.

Next to that we utilize a highly efficient drying technique which does not only reduced our energy consumption with 50 % compared to conventional forced air drying, but also allows us to manufacture uniform, lightweight, low shot and stable board up to a thickness of 4 inches at high consistency, quality and performance.

SoliBoard is produced with a very tight thickness tolerance and offer unparalleled flatness. As a result the SoliBoard, compared to other types of board, offers better machining characteristics in CNC cutting. With SoliBoard you can easily tailor the board into a precision machined shapes for domestic boilers and heater. We know for sure, that once you have been working with our boards, you will never want to go back.

The SoliBoard product range is quickly expanding and is not only offered in various chemical compositions, but also is available in high strength versions. Even though we believe that our standard board, as result of our superior production technology, is already offering very high strength at standard density, we have developed new grades which are even more durable and tough. As our core company strategy is innovation, we will be adding new products to the existing range in the near future.

Basically our SoliBoard product range could be divided into 3 groups:

- Standard boards which are available in both RCF and LBP fiber

- Special series boards like our SoliBoard PCW INO

- High Strength series board and Millboards

The standard board range is our main product range and consists of 3 products; SoliBoard X-grade based on Refractory Ceramic fiber with a classification temperature of 2300°F, SoliBoard ZR-grade based on Refractory Ceramic Fiber with a classification temperature of 2600°F and the SoliBoard ULS® based on Low Bio Persistence Fiber.

The special series boards product range is likely to expand in the very near future. With these products we cover applications at very high temperatures or with special requirements in mind; like the SoliBoard PCW INO. SoliBoard PCW INO is our unique 2912°F classification temperature board manufactured from Mullite fibers and a small percentage of our SoliWool HA (High Alumina) fiber. Tested independently for 24 hours at 2912°F we have achieved a Permanent Linear Change (PLC) of 0,8 %!

In the overview underneath we have listed the 3 standard board grades together with the SoliBoard PCW INO grade.

All products in the SoliWool ULS fiber product range, like the SoliBoard ULS, meet the requirements specified under NOTE Q of European Regulation 1272/2008. All SoliBoard ULS products are therefore exonerated from labelling requirements in Europe.

SoliBoard is available in a thickness range from 3/8 till 4 inches. The standard boards are 47 1/4×36 inches and packed in full telescopic carton boxes. The carton boxes are stacked to created a total pallet heigth of approximately 7 feet.

The main advantage of our carton box packaging is that you will be able to unstack the pallet more easily and it avoids damages from transport or internal handling.