The SoliBulk product range is the basis of nearly all our products as the majority of our bulk production gets converted at our own factory into papers, boards and felts. We offer our SoliBulk in a wide variety of specifications tailored to the commonly known applications from raw material for Vacuum Forming to general lubricated bulk which can be used for filling and stuffing voids and gaps in furnace linings. To ensure that the products are meeting the requirements in the application we also provide special grades which can be deshotted, chopped, or provided at extra length.

- Raw material for Vacuum Forming

- Fiber for yarn and rope manufacturing

- Speciality filler to increase strength of insulating castables

- Major ingredient to manufacture mastics and coatings

- General refractory applications like filling and stuffing voids and gaps in furnace linings

- Deshotted and milled fiber for paints and pastes

- Engineered and deshotted fibers for catalyst converters and brake pads in the automotive industry

- Blown or injected fiber for double wall chimneys and infill for airgaps.

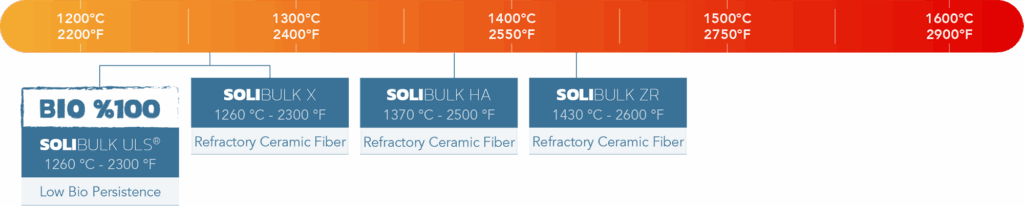

We offer our SoliBulk in both refractory ceramic fiber grades as well as our famous Generation III, Ultra Low Shot low bio persistence fibers which allow maximum flexibility to the end customers. It goes without saying that our SoliBulk ULS meet the requirements specified under NOTE Q of European Regulation 1272/2008. All SoliBulk ULS fiber products are therefore exonerated from labelling

requirements in Europe.

SoliBulk can be used for a large varity of applications using secondary processing like: vacuum formed shapes, yarn and rope manufacturing, reinforcement of insulating castables, raw material for mastics and coatings, blown or injected fiber for double wall chimneys and infill for airgaps and cavities in furnaces. Please note that each of these final applications require fiber specifically tailored for the final application. This either be as simple as selecting a lubricated for unlubricated bulk fiber, but in most cases also require a perticular fiber length.

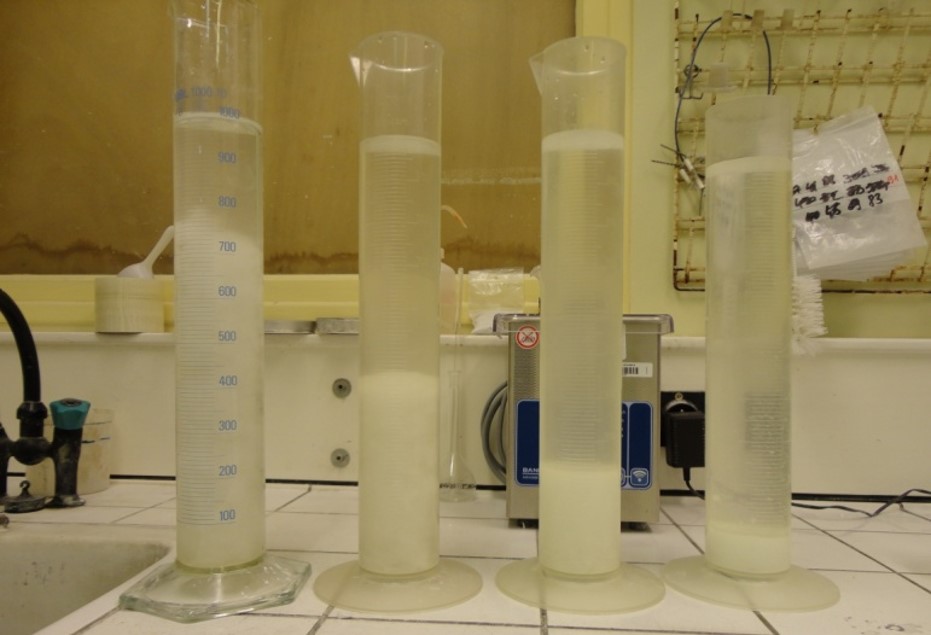

The normal definition for the fiber length is the ‘beaker value’ or ‘BV’. This beaker value is defined by putting a fixed weight of dry fiber in a beaker filled with water. The higher the fiber sets in the beaker, the higher the beaker value. As a result the beaker value is representing the volume to weight ratio.

In over 20 years of doing business in the high temperature industry, we never came accross a vacuum forming company who would tell us the specific ‘beaker value’ they were looking for. They defined their fiber to the length or the expected ‘touch and feel’. For that reason we are using straight forward identification for our standard bulk fiber types:

- Chopped – high density VF shapes, special grades and mastics

- Short – standard VF manufacturing and mastics

- Medium – blown fibers for double walled chimneys

- Large – void/joint fillers in furnaces

Extra Large – production of rope and textiles

All products offered in the SoliBulk product range share the Ultra Low Shot technology which has been developed to achieve the highest possible thermal insulation value, provides a extremely high fiber index, and specifically for the SoliBulk to differentiate from other suppliers with a higher yield in secondary processing.

What this means is that your vacuum forming shapes will be more rigid at the same input, or you could optimize your process to reduce your raw material consumption in the range of 10-15 %. In applications like double walled chimneys, where the bulk is blown to fill the cavity, you will experience that with lower filling rates you will achieve the same cold face temperatures.

With our new packaging equipment we are able to supply our bulk fiber products in tight and compressed shrinkwrap bags which are allow minimizing time required for unpacking whilst ensuring maximum consistency of the fiber length troughout the bag. We do this by a using a multi axle compression which ensure a consistent fiber length throughout the bag.

Short and chopped fiber can be packed with a higher density in the bag and for that reason has more material per truck or container. Long fiber, which is mainly used for infill, is not heavily compacted to ensure a stable fiber length and consistency within the bag. Each pallet holds 30 bags with a dimension of 600x400x400 mm. The weight per bag is varying based on the desired fiber length in final application.

Please go to the product selector on the website for the information on the various chemical compositions in the SoliBulk product range and to download the datasheets and material safety datasheets.