Welcome to Vulcor Insulation

Introducing revolutionary insulation solutions for the industry

Introducing revolutionary insulation solutions for the industry

Based and rooted in the Netherlands, Vulcor Insulation is serving the refractory industry with the first commercialized Generation III, Ultra Low Shot fiber. We are responsible for the development, technical support, certification, sales support, logistics, distribution of the SoliWool™ fiber based solutions. In a market which is very conventional, we bring a new story of energy saving solutions.

Together with our industrial insulation solutions, we serve a wide range of markets and applications, primarily focusing on high-temperature environments up to 1700°C (3100°F). We have an extensive team of highly experienced people and supply projects around the globe. We are glad to team up with local partner companies. This allows us to offer you global service with local attention. Vulcor Insulation can help you save energy.

Born and raised from the ambition to deliver the best performing thermal insulation solutions for the industry. Pioneering…

Read moreAs Vulcor we are proud to introduce the first Generation III, Ultra Low Shot fiber in the world. Not as a premium, or only…

Read moreVulcor Insulation is bringing you the latest generation high temperature fiber products.

If you were to see the factory where we manufacture our SoliWool™ fiber solutions, it is hard to imagine that back in 2017 it was just a ‘Greenfield’ plan. Today our state of the art factory spans 75.000 m2 (800.000 ft2) and manufactures the most advanced high temperature fibers products.

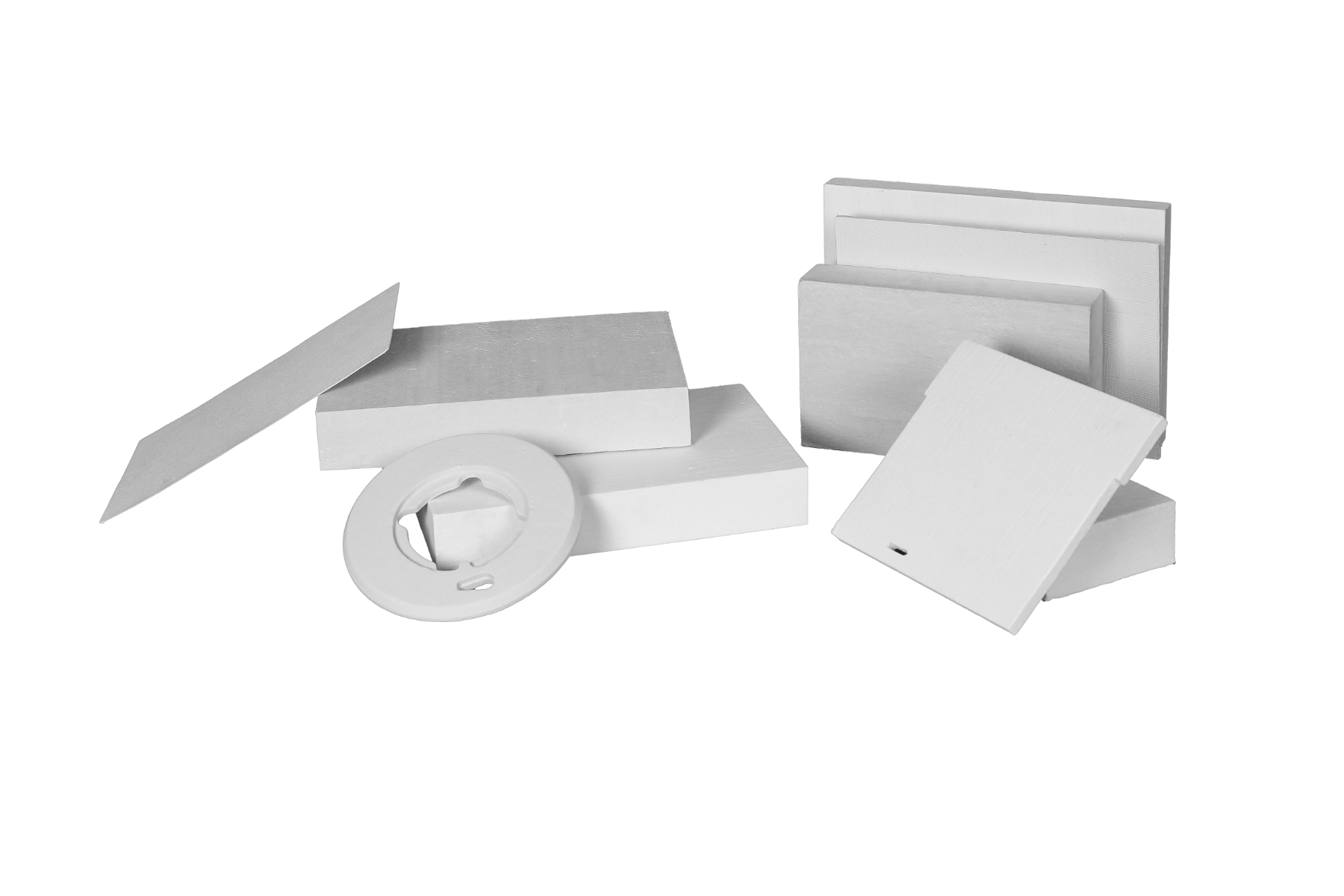

The SoliWool™ product range consists of engineered bulk fiber, Ultra Low Shot technology blankets, dust free and smooth papers, flexible felts, high tech manufactured board products, tailored to shape vacuum formed shapes and one of the widest ranges of fiber modules.

All the SoliWool™ are manufactured with our Generation III, Ultra Low Shot technology. SoliWool™ is outperforming conventional refractory ceramic fibers (RCF) and low bio persistence fibers (LBP) on thermal conductivity, mechanical strength and handling.

Industrial heating insulation is often far less efficient than that of a home. While homeowners are mindful of their monthly electricity bills, industrial furnaces operating at 1000°C (1800°F) lose significantly more energy when poorly insulated. With their complexity, insulation is rarely a priority. Our high-performance insulation maximizes efficiency per cubic unit, boosting energy savings and sustainability.

The SoliWool product range is one of the most extensive fiber ranges on the market. Targeted to provide the best possible thermal insulation solution for use in high temperature applications. We offer multiple Refractory Ceramic Fiber chemistry compositions, a range of Low Bio Persistence Fibers and a range of converted products based on Poly Crystalline Wool up to 1700°C (3100°F).

SoliBoard is the top choice for domestic boilers, heaters and furnaces, resistant to temperatures up to 1700°C (3100°F). Our innovative continuous production process ensures a lightweight, strong, and perfectly flat board, ideal for CNC precision machining. The tight tolerances and high stability make it a sustainable choice for efficient heat insulation.