Description

Our RhinoPhen product range consists of closed cell phenolic foam blocks, focusing on achieving the highest possible thermal insulation value at minimum thickness. We offer this product range in a wide range of densities and specifications. Whilst the main application is targeted the conversion for pipe insulation, we target the fire protection applications.

All products in the Rhinophen product range are combining one other unique feature next to the highest thermal insulation value and mechanical strength; it’s fire performance.

Rhinophen does not have a defined melting temperature unlike most thermoplastic and even some inorganic insulation materials. In case of fire it will develop a carbonaceous layer on the exposed surface which is protecting the deeper layers of the material. It does not mean that Rhinophen is fit to perform long term at high temperature exposure, but it does mean that Rhinophen has excellent potential for use in fire protection systems. Using this phenomenon we have been able to develop new applications with the Rhinophen product range, like doors and seperation walls.

Firesafety, to our perspective, is much more than focussing on fire behavior, smoke development or just fire resistence. It is a combination for these 3 main parameters that are leading to a firesafe solutions.

- A good fire behavior as a product is difficult to burn or has low contribution to the spread and development of the fire;

- An excellent fire resistant withstanding the heat and keep the non exposed side safe;

- And very low smoke emissions which are allowing safe exit in case of emergency.

And Rhinophen is offering excellent performance on all these 3 main parameters combined in one product. The team of Vulcor Insulation is keen to support you with development of fire safe solutions using Rhinophen as core material for doors and seperation walls targeting both thermal insulation and fire safety.

Benefits

- Excellent insulation performance

- High fire resistance and good fire behavior

- Excellent insulation performance

- Low heat storage

- High strength

- Easy to cut and create any shape or form

- Excellent thermal stability

Typical applications

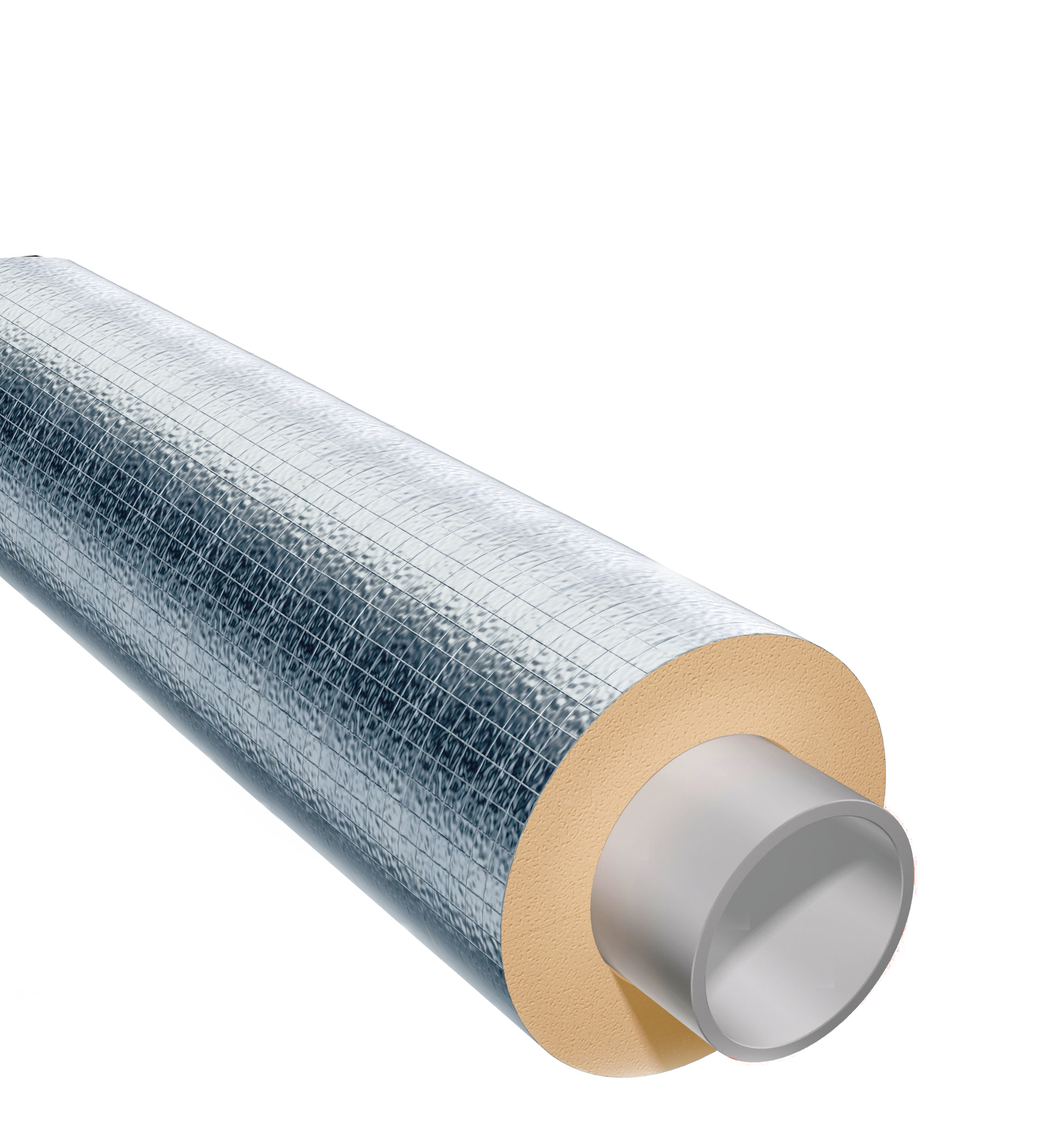

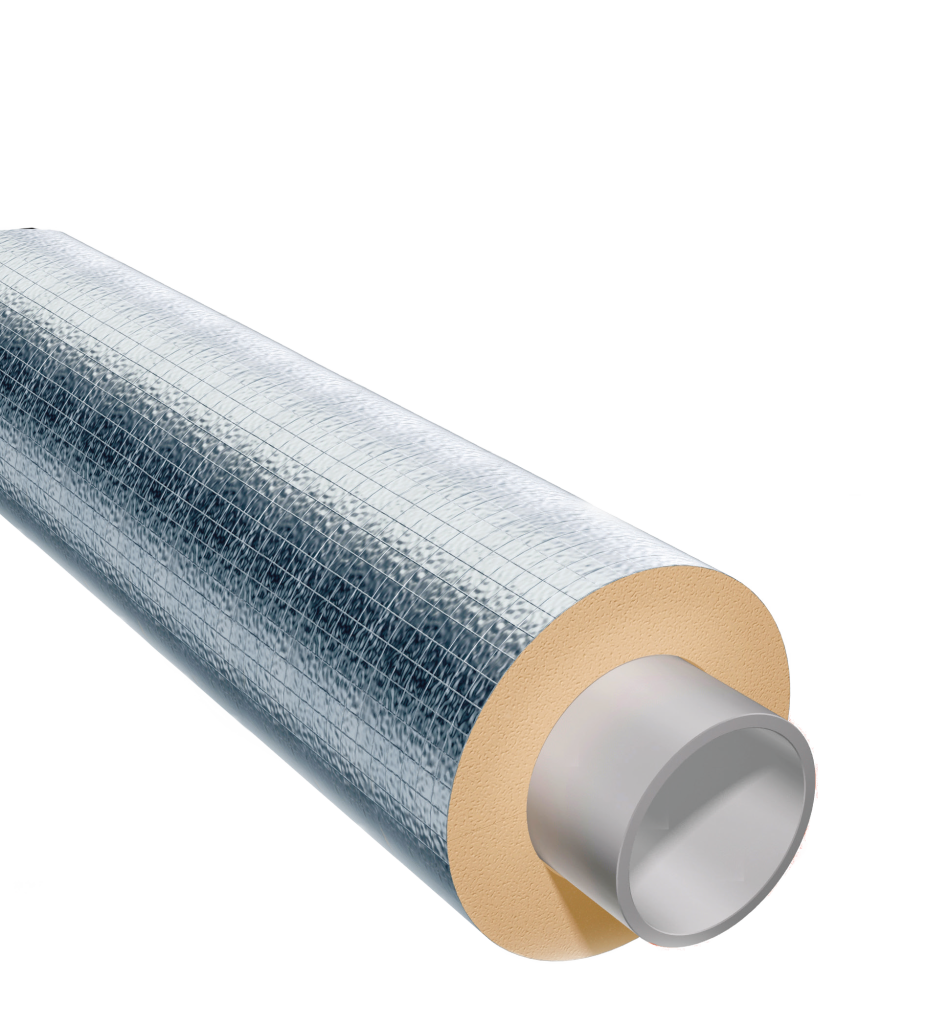

- Pipe insulation for the HVAC market

- Fire resistant core material in doors and composite panels

- Pipe insulation for application in the chemical process-and cold storage industry

- Pipe supports from high density Rhinophen

- General technical insulation of tanks, ducts, vessels and technical installations

Type

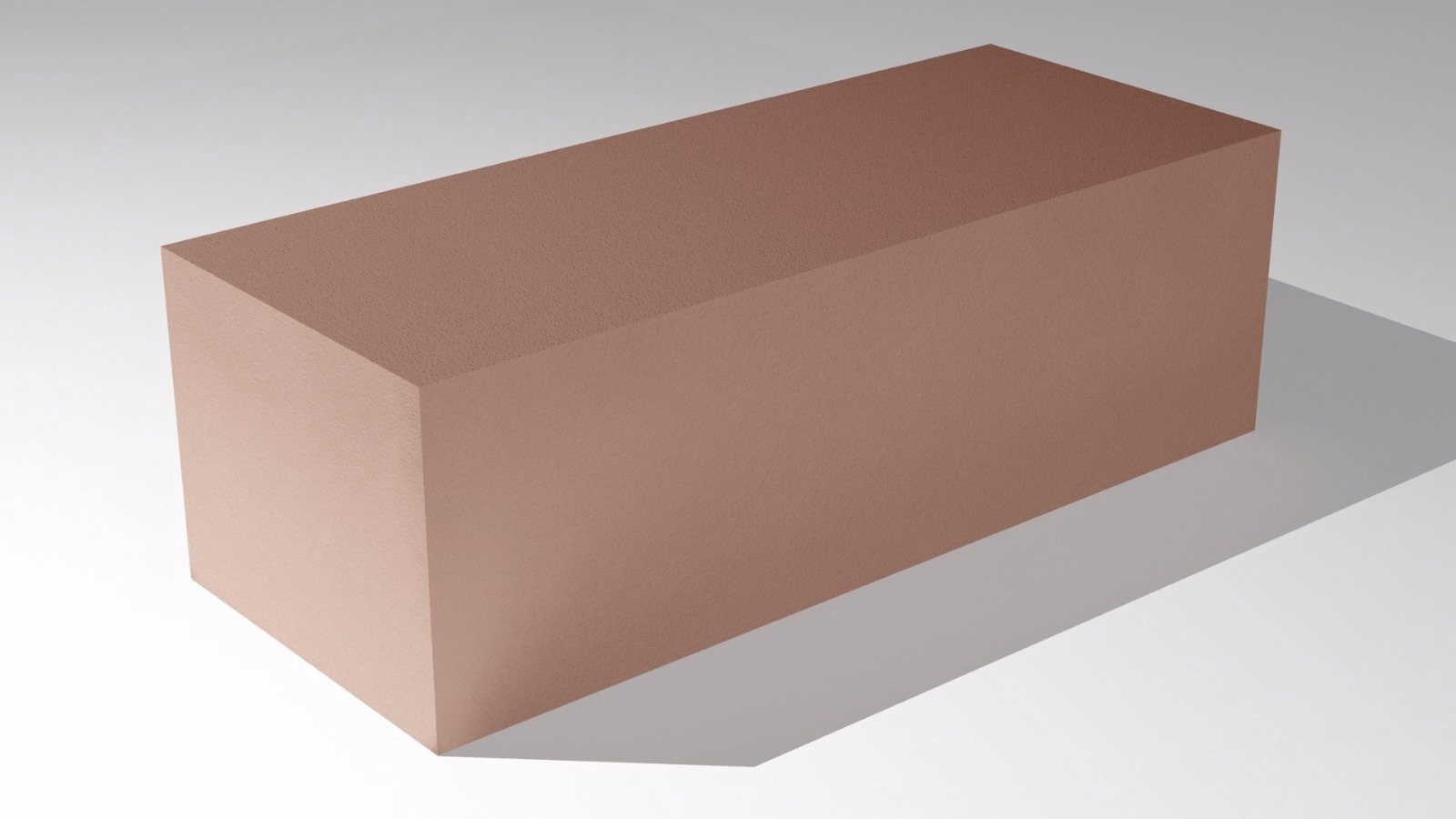

Block type insulation based on closed cell phenolic foam.

Temperature range

Rhinophen will maintain its performance at continuous operating temperatures of – 50°C to 120°C (-58°F to +230°F).

Under special installation conditions Rhinophen can be used in petrochemical applications up to cryogenic temperatures.

Short term exposures which could exceed the

recommended continuous operating temperatures are pending on the application.

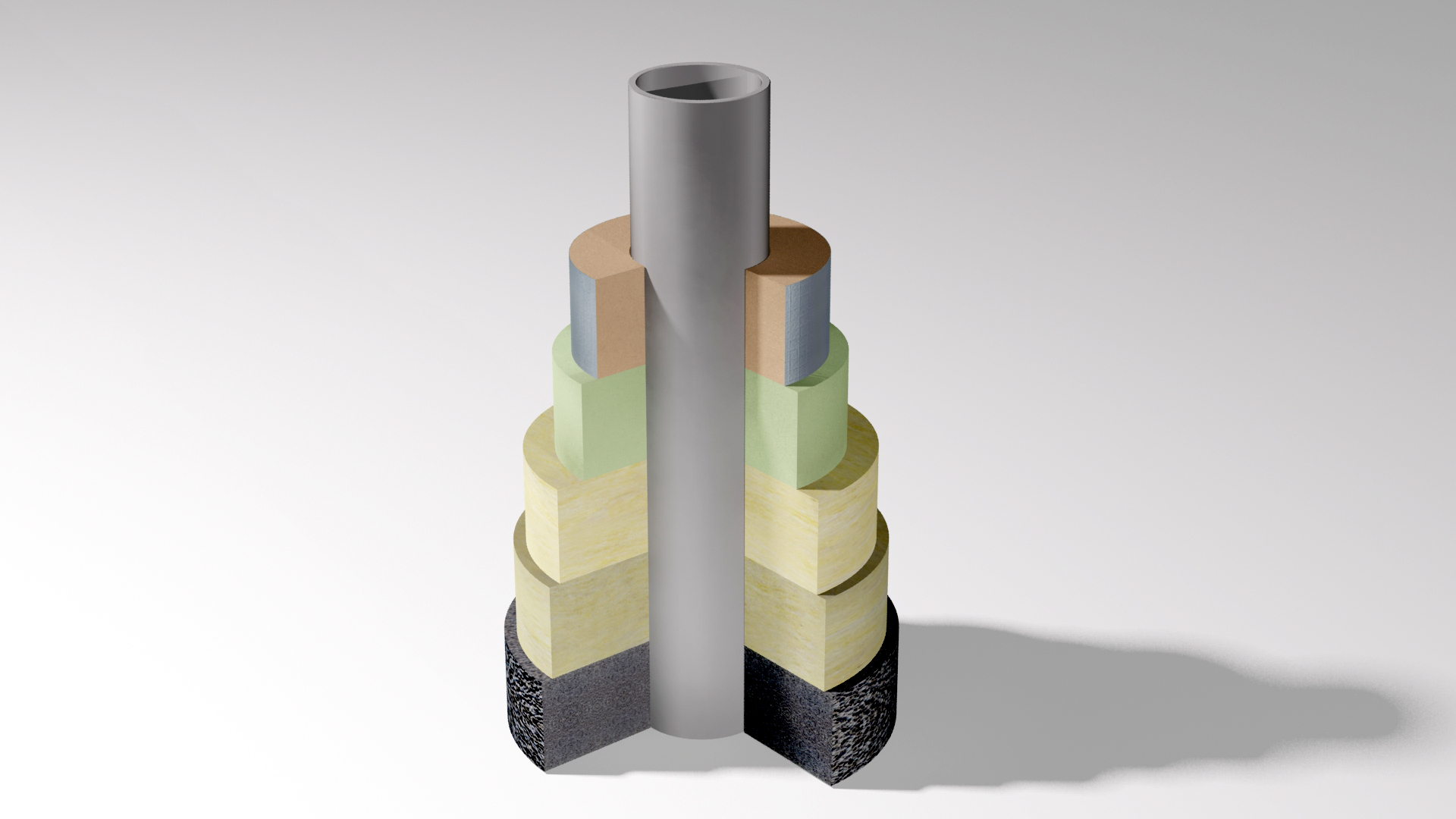

Product range

Rhinophen is part of an extensive product range supplied by Vulcor Insulation. Vulcor Insulation is supplying insulation solutions from cryogenic to high temperature applications. All products offered by Vulcor are manufactured in house or sourced from exclusive trusted third party partners.

Technical support

Vulcor Insulation provides specifiers and customers with guidance on all aspects of the materials selection for their application, the installation and compliance with relevant regulations and performance standards.

For additional information about product performance, or to identify the recommended product for your application, please contact the team at Vulcor Insulation.

Availability

Rhinophen is manufactured as a block type insulation with a typical size of 2500x1000x800 mm (100x40x32 inch) and is available in densities ranging from 40 kg/m3 to 160 kg/m3 (2.5 to 10 PCF).

Rhinophen blocks are individually packed in a black plastic foil wrap and can be supplied up till 39 blocks per truck or 40′ HC container. A block of Rhinophen can be converted to nearly any shape and size by CNC cutting to provided tailored solutions for special fire- or thermal insulation solutions.

Properties

| Properties measured | Standard | Unit | 40 | 60 | 80 | 120 | 160 |

|---|---|---|---|---|---|---|---|

| Density | ASTM D1622 | PCF | 2.5 | 3.7 | 5 | 7.5 | 10 |

| Continuous use temperature*3 | °F | -58 to 230 | -58 to 230 | -58 to 230 | -58 to 230 | -58 to 230 | |

| Compressive strength | ASTM D1621 | ||||||

| Parallel to rise | PSI | 22 | 58 | 102 | 145 | 218 | |

| Perpendicular to rise | PSI | 18 | 50 | 87 | 123 | 145 | |

| Tensile strength | ASTM D1623 | ||||||

| Parallel to rise | PSI | 22 | 58 | not tested | not tested | not tested | |

| Perpendicular to rise | PSI | 20 | 54 | not tested | not tested | not tested | |

| Closed cell content | ASTM D2856 | % | 95 | 92 | 90 | 85 | 85 |

| Dimensional stability | EN1601 | % | < 1 | < 1 | < 1 | < 1 | < 1 |

| Water absorption | EN13087 | % | < 3 | < 3 | < 3 | < 3 | < 3 |

| Water vapour transmission | EN1286 | um | 30 | 45 | 50 | 60 | 75 |

| Fireproperties | |||||||

| Euroclass (SBI) | EN13501-1 | ||||||

| Naked product | B-s1,d0 | B-s1,d0 | B-s1,d0 | not tested | not tested | ||

| Pipe section with ASJ facing*1 | BL-s1,d0 | not tested | not tested | not tested | not tested | ||

| Surface burning characteristics | ASTM E84-21a | ||||||

| Flame spread index | 10 | not tested | 0 | not tested | not tested | ||

| Smoke development index | 0 | not tested | 5 | not tested | not tested | ||

| UL-C surface burning characteristics | CAN/ULC-S102-03/S127-04 | ||||||

| Flame spread index | < 10 | not tested | not tested | not tested | not tested | ||

| Smoke development index | < 10 | not tested | not tested | not tested | not tested | ||

| Thermal conductivity value *2 | EN12667 (equivalent to ASTM C518) @ 75°F | ||||||

| Initial | BTU•in/hr•ft2•°F | 0.146 | 0.167 | 0.201 | 0.236 | 0.278 | |

| Aged | BTU•in/hr•ft2•°F | 0.173 | 0.194 | 0.236 | 0.278 | 0.347 | |

| (verified after 26 weeks @ 158°F) |