Description

Introducing SoliBloc™ PRO modules, an exceptional high-temperature monolithic fiber module developed by our R&D team. Utilizing our 1430°C rated SoliWool ZR we have developed a truly unique fiber module system with a classification temperature of 1500°C and capable to perform in application operating till 1370°C continuously.

The durability of SoliBloc™ PRO modules is truly unmatched, setting new standards in the industry. With an exceptional strength and high temperature resistence that surpasses all other available RCF module products in the market, these modules are engineered to endure even the most challenging environments.

SoliBloc™ PRO modules are filling the void between the standard 1430°C RCF-Zr modules and the much higher positioned 1600°C rated PCW based modules. But SoliBloc™ PRO modules are much more than that. As a result of the very high density these modules are very strong and are designed to withstand high gas velocities without fiber erosion.

The density of the SoliBloc™ PRO modules is no less then 280 kg/m3. Compared to other types of modules this is resulting in a very high fiber index. Therefore, these modules are not just targeting a higher temperature application, but can also be used in applications where a high strength and erosion resistence are required.

SoliBloc™ PRO are based on our Generation III SoliWool ZR fiber, but can operate in higher continuous use temperatures up till 1370°C. For this reason, SoliBloc™ PRO can be used in applications which would be close to, on, or over the limit of standard modules.

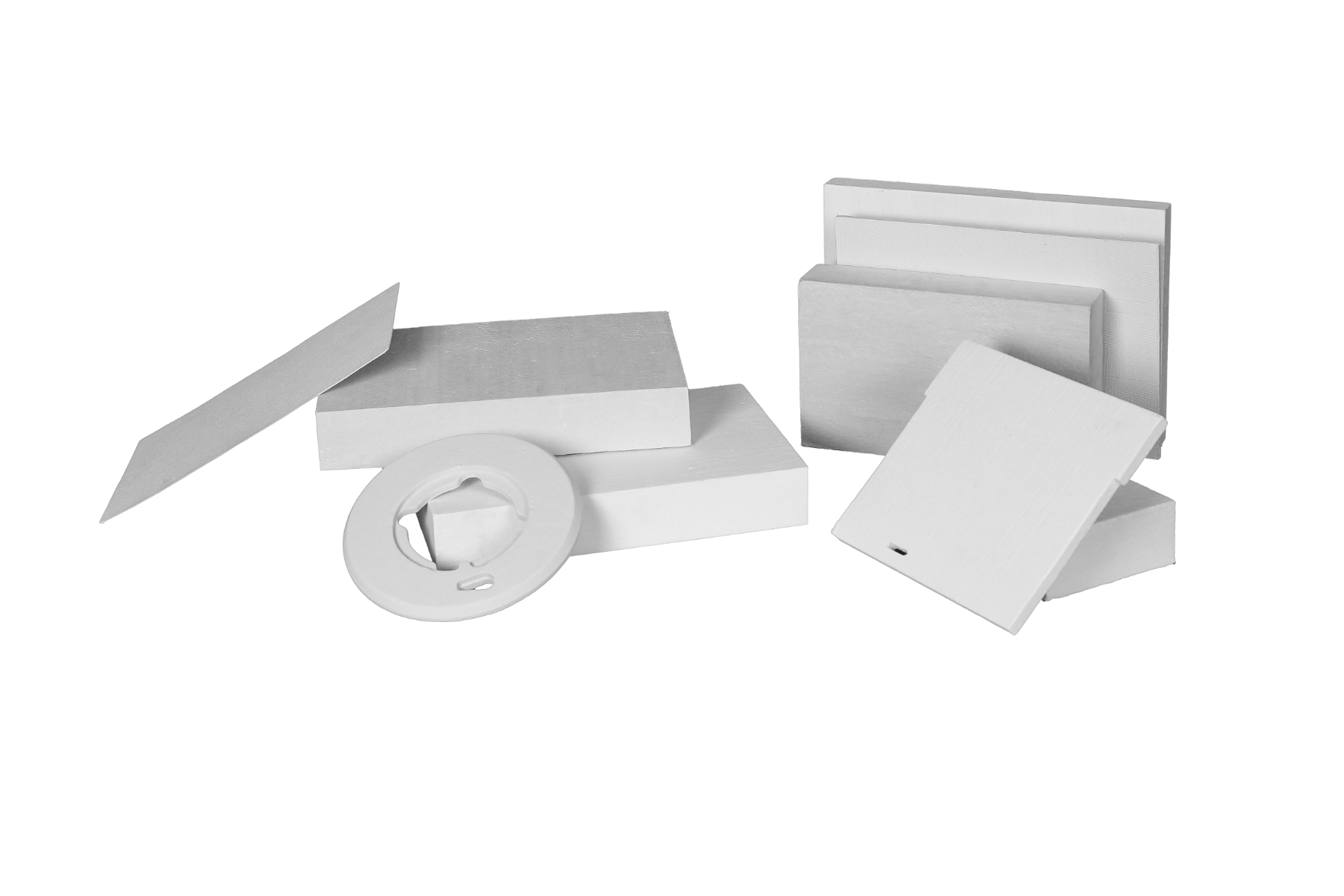

These modules, like our other SoliBloc™ products, are based on compressed sections of SoliSlab™ arranged in an edge grain orientation. Inside the SoliBloc™ PRO we have installed our center fix ’hook and bracket’ anchoring system based on AISI 321 stainless steel.

SoliBloc™ PRO is part of the SoliBloc monolitic fiber module product range. With a variety of 2 Refractory Ceramic Fiber (RCF) grades, the famous ‘ULS®’ Low Bio Persistence Fiber grade and this unique SoliBloc™ PRO, we are offering the most extensive range temperature range of monolitic fiber modules in the market today. With our different chemical compositions we are able to provide a solution to nearly every atmosphere or temperature.

Benefits

- Low shot technology

- Excellent insulation performance

- Withstands high gas velocities

- Excellent thermal stability

- Targeted to operate at high continuous use temperatures

- Competitively priced to PCW fiber based modules

Typical applications

- Thermal insulation for furnace lining

- Thermal insulation for Petrochemical Industry (like process heaters, reformers, cracker units)

- Chemically stable insulation for Steel Treatment (reheating-, annealing-, and rotary hearth furnaces)

- Linings in Ceramic Industry (tunnel kilns and intermittent kilns)

- General technical insulation of furnaces and technical installations

Type

Monolithic Fiber Modules manufactured from high temperature Refractory Ceramic Fiber

Temperature range

SoliBloc™ PRO modules have a classification temperature of 1500°C and can be used up till 1370°C continuously.

The maximum continuous use temperature provided on the website is a guideline and only applicable in a clean oxidizing atmosphere.

Product range

SoliBloc™ PRO modules are part of an extensive product range supplied by Vulcor Insulation. Vulcor Insulation is supplying insulation solutions from cryogenic to high temperature applications. All products offered by Vulcor are manufactured in house or sourced from exclusive trusted third party partners.

Technical support

Vulcor Insulation provides specifiers and customers with guidance on all aspects of the materials selection for their application, the installation and compliance with relevant regulations and performance standards.

For additional information about product performance, or to identify the recommended product for your application, please contact the team at Vulcor Insulation.

Availability

We offer our SoliBloc™ PRO in standard straight 305x305 mm modules and in thicknesses from 200 mm. Technically, we would be able to make these modules in smaller thicknesses. However, as these modules are targeted for use in very high temperature environments, it makes no sense to insulate with a thinner lining from environmental perspective.

In standard size the modules are packed in carton boxes of 320x320x970 mm (holding multiple modules) with 24 boxes per pallet. Please refer to the list below for packaging details of the SoliBloc modules, other sizes are available on request.

For projects we also offer tailor modules to meet specific engineering requirements, such as L-shaped corner modules and other special shapes. Please let us know if you require any further information or have specific engineering needs. We are dedicated to providing high-quality fiber modules that meet your thermal insulation and strength requirements.

| Length (mm) | Width (mm) | Thickness (mm) | Pieces (carton) | Pieces (pallet) |

|---|---|---|---|---|

| 305 | 305 | 200 | 5 | 120 |

| 305 | 305 | 250 | 4 | 96 |

| 305 | 305 | 300 | 3 | 72 |

Properties

| Properties measured | Standard | Unit | SoliBloc™ PRO |

|---|---|---|---|

| Grade | RCF | ||

| Colour | white | ||

| Classification temperature | °C | 1500 | |

| Continuous use temperature | °C | 1370 | |

| Density | kg/m3 | 280 | |

| Thickness range | mm | ≥ 200 | |

| Permanent linear shrinkage | EN1094-7 | % | |

| @1400°C | < 2 | ||

| Thermal conductivity | ASTM C201 | W/mK | |

| @ 200°C | 0,07 | ||

| @ 400°C | 0,1 | ||

| @ 600°C | 0,15 | ||

| @ 800°C | 0,21 | ||

| @ 1000°C | 0,3 | ||

| Chemical composition | ISO12677 | % | |

| SiO2 | 44-50 | ||

| Al2O3 | 35-38 | ||

| ZrO2 | 15-17 | ||

| Other | < 1 |

Properties

| Properties measured | Standard | Unit | SoliBloc™ PRO |

|---|---|---|---|

| Grade | RCF | ||

| Colour | white | ||

| Classification temperature | °F | 2750 | |

| Continuous use temperature | °F | 2500 | |

| Density | PCF | 17.5 | |

| Thickness range | inch | ≥ 8 | |

| Permanent linear shrinkage | EN1094-7 | % | |

| @2550°F | < 2 | ||

| Thermal conductivity | ASTM C201 | BTU·in/hr·ft2·°F | |

| @500°F | 0.51 | ||

| @1000°F | 0.90 | ||

| @1500°F | 1.49 | ||

| @1800°F | 1.98 | ||

| @2000°F | 2.36 | ||

| Chemical composition, | ISO12677 | % | |

| SiO2 | 44-50 | ||

| Al2O3 | 35-38 | ||

| ZrO2 | 15-17 | ||

| Other | < 1 |