Description

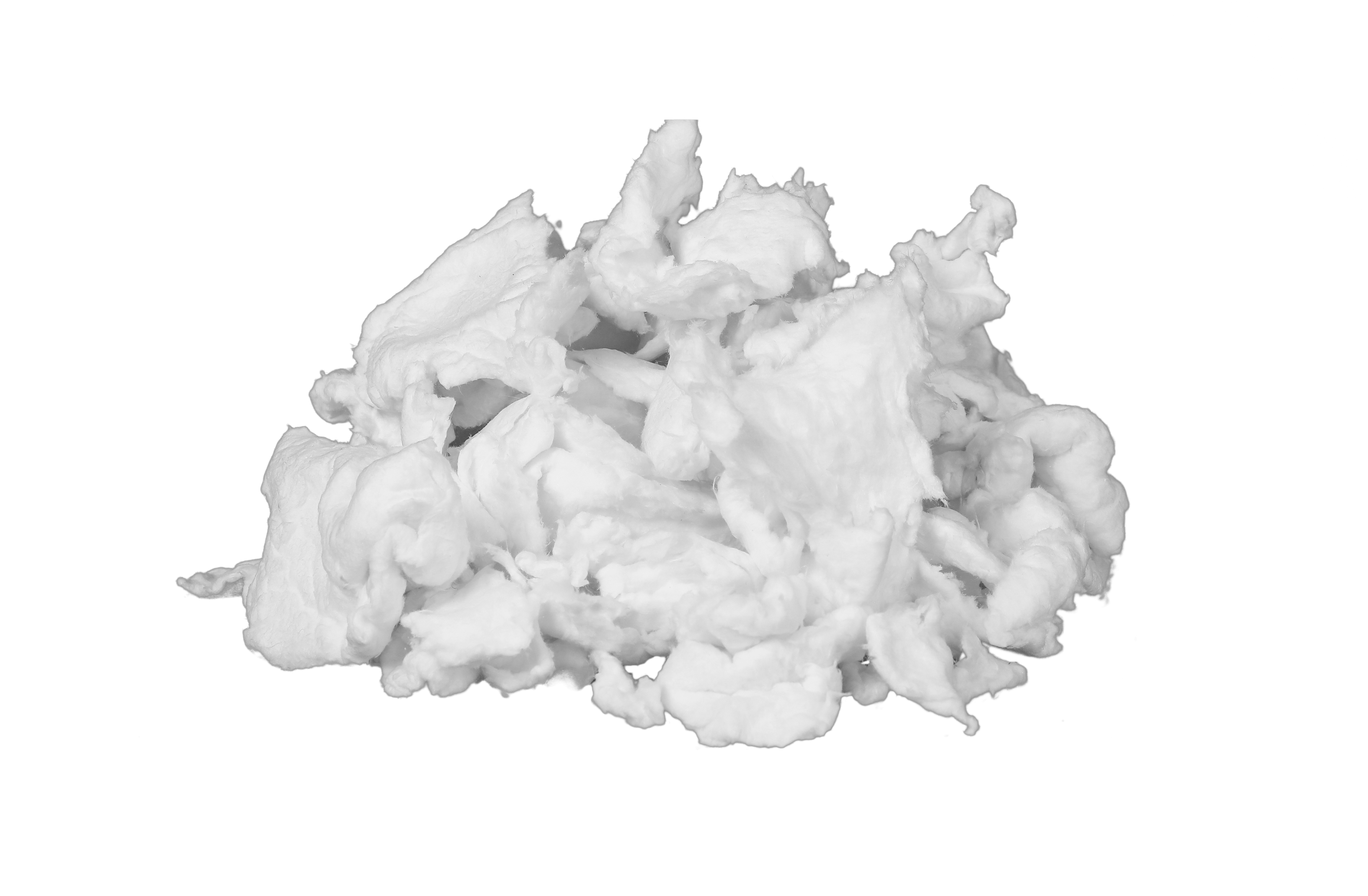

SoliBulk™ ULS® is our famous Generation III, Ultra Low Shot fiber technology, low bio persistence (LBP) bulk in the SoliBulk™ product range. With a classification temperature of 1260°C. It is engineered to perform in a wide range of applications up till 1100°C continuously.

Our Ultra Low Shot fiber technology is enabling a higher fiber index and lower shot contents. In result, you will benefit from a higher yield in the further processing of the fiber, or enhance properties of your final product. In wet processes, the impact of shot content in bulk fiber on yield is often underestimated. In Vacuum Forming production, shot particles tend to sink in the liquid mixture, reducing the volume per kilogram of bulk fiber used.

With the Ultra Low Shot technology we typically improve the yield by 15-30 % over Generation I and Generation II products. By us utilizing the latest fiber technology, you will experience stronger and higher quality Vacuum Formed shapes, while optimizing the use of raw materials.

We offer our SoliBulk™ ULS® as standard product, and as engineered bulk. As engineered bulk, we tailor our SoliBulk with additional processing like deshotting and milling. For specific requirements on our SoliBulk Engineered bulk products or if you need additional information, please contact the team at Vulcor Insulation.

All products in the SoliWool™ ULS® product range, like the SoliBulk™ ULS®, meet the requirements specified under NOTE Q of European Regulation 1272/2008. SoliBulk™ ULS® products are therefore exonerated from labelling requirements in Europe.

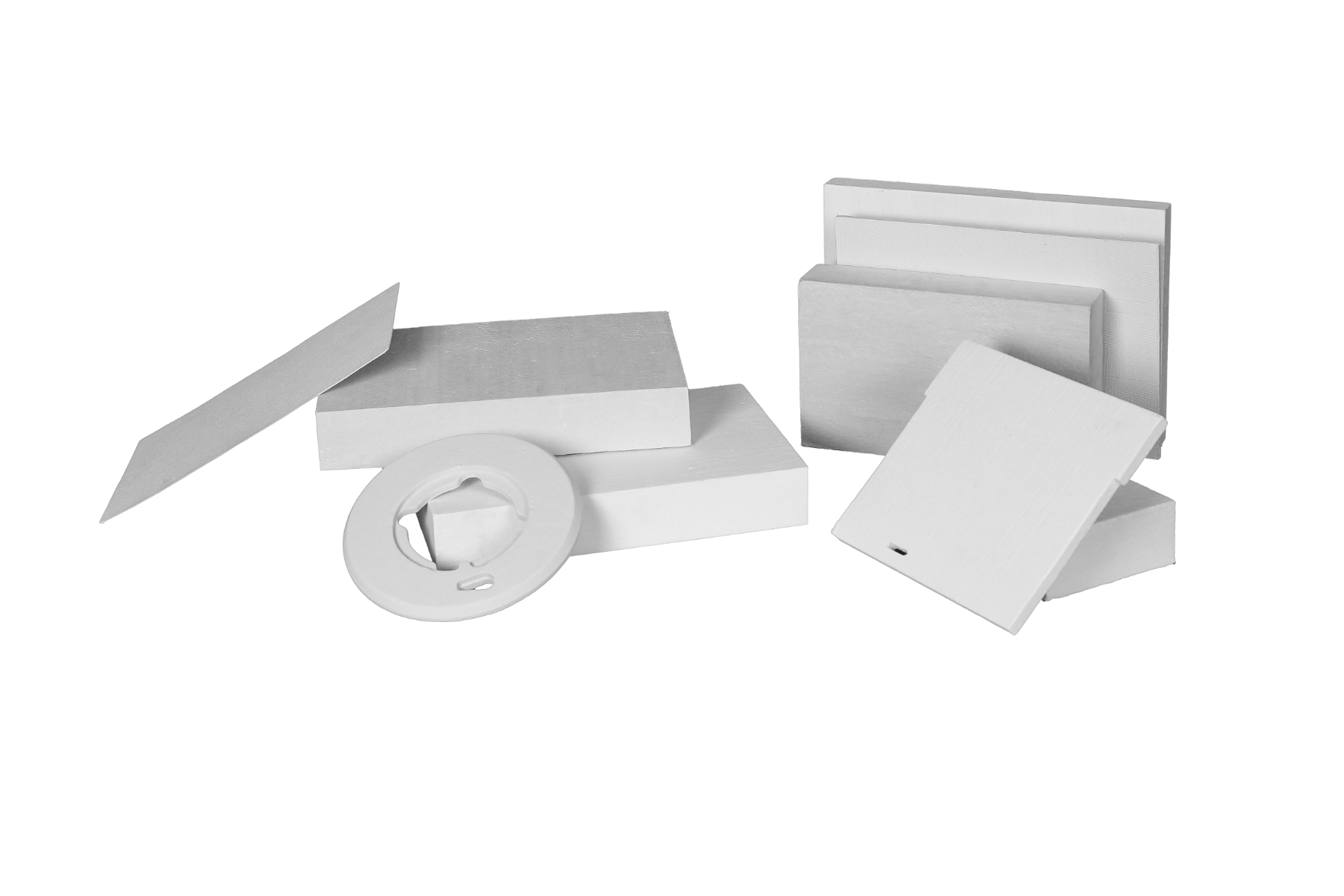

SoliBulk™ ULS® can be used for a large variety of applications using secondary processing like: vacuum formed shapes, reinforcement of insulating castables, and raw material for mastics and coatings. Long fibers are used for yarn and rope manufacturing, get blown or injected fiber for double wall chimneys, or used as infill for airgaps and cavities. Please note that each of these final applications require fiber specifically tailored for the final application. This might be as easy as selecting a lubricated for unlubricated bulk fiber, but in some cases also require a particular fiber length.

All grades of SoliBulk are available in different types designed for various applications:

- Lubricated bulk – used for yarn/ textile, joint filler;

- Unlubricated bulk – used for mastics and vacuum forming.

We offer all bulk fibers in different styles in line with the application requirements:

- Chopped – high density VF shapes and mastics

- Short – standard VF manufacturing and mastics

- Medium – infill for double walled chimneys

- Long – void/joint fillers, dry injected fibers and textiles

SoliBulk™ ULS® is part of the SoliBulk product range. SoliBulk productrange is one of the most extensive product ranges targeting a wide range of atmospheres and temperatures, providing tailored solutions to meet specific requirements. This versatility enables us to deliver high-performance insulation products that excel, giving you the ability to make the best quality products and optimizing customer satisfaction.

Benefits

- Low shot technology

- Higher yield in secondary processing

- Excellent insulation performance

- High handling strength

- Excellent thermal stability

- Resistant to thermal shock

- Proven technical solution

- Exonerated of carcinogenic classification under Note Q

Typical applications

- Raw material for Vacuum Forming process;

- Raw material for insulating castables, mastics and coatings;

- Filling and stuffing of voids and gaps in furnace lining;

- Injected/blown fiber in double wall chimneys;

- Long fibers for yarn production (textiles);

- General technical insulation of furnaces and technical installations.

Type

Loose insulation wool from high temperature low bio persistence fiber (LBP).

Temperature range

SoliBulk ULS-grade has a classification temperature of 1260°C and advised for maximum continuous use at 1100°C.

The maximum continuous use temperature provided on the website is a guideline and only applicable in a clean oxidizing atmosphere.

Product range

SoliBulk is part of an extensive product range supplied by Vulcor Insulation. Vulcor Insulation is supplying insulation solutions from cryogenic to high temperature applications. All products offered by Vulcor are manufactured in house or sourced from exclusive trusted 3rd party partners.

Technical support

Vulcor Insulation provides specifiers and customers with guidance on all aspects of the materials selection for their application, the installation and compliance with relevant regulations and performance standards.

For additional information about product performance or to identify the recommended product for your application, please contact the team at Vulcor Insulation.

Availability

SoliBulk is packaged on our new state-of-the-art production line, targeted to minimize deviation of the fiber length throughout the packaging. With our new packaging equipment we are able to supply our bulk fiber products in tight and compressed shrinkwrap bags. This allows minimizing time required for unpacking and ensures consistency of the fiber length. We do this by a using a multi axle compression which ensure a consistent fiber length throughout the bag.

Each pallet has 30 bags with a dimension of 600x400x400 mm. The weight per bag is varying based on the desired fiber length in final application. Short and chopped fiber can be packed with a higher density in the bag and for that reason has more material per bag. Long fiber, which is mainly used for infill, is not heavily compacted to ensure a stable fiber length and consistency within the bag.

| Type | kg/bag | bag p/pallet | kg/pallet |

|---|---|---|---|

| Chopped | 20 | 30 | 600 |

| Short | 18 | 30 | 540 |

| Medium | 15 | 30 | 450 |

| Long | 12 | 30 | 360 |

Properties

| Properties measured | Standard | Unit | SoliBulk ULS-grade |

|---|---|---|---|

| Grade | LBP | ||

| Colour | white | ||

| Classification temperature | °C | 1260 | |

| Continuous use temperature | °C | 1100 | |

| Beaker value (fiber length), ml | |||

| Chopped | 60 - 100 | ||

| Short (VF) | 140 - 200 | ||

| Medium | 250 - 400 | ||

| Long | 450 - 600 | ||

| Mean Fiber Diameter | micron | 2.5-4 | |

| Short contents | Jetsieve | > 45 um | < 35% |

| Chemical composition, % | EN12677 | ||

| SiO2 | 63-68 | ||

| CaO | 26-33 | ||

| MgO | 3-7 | ||

| Other | < 0.8 |

Properties

| Properties measured | Standard | Unit | SoliBulk ULS-grade |

|---|---|---|---|

| Grade | LBP | ||

| Colour | white | ||

| Classification temperature | °F | 2300 | |

| Continuous use temperature | °F | 2000 | |

| Beaker value (fiber length), ml | |||

| Chopped | 60 - 100 | ||

| Short (VF) | 140 - 200 | ||

| Medium | 250 - 400 | ||

| Long | 450 - 600 | ||

| Mean Fiber Diameter | micron | 2.5-4 | |

| Short contents | Jetsieve | > 45 um | < 35% |

| Chemical composition, % | EN12677 | ||

| SiO2 | 63-68 | ||

| CaO | 26-33 | ||

| MgO | 3-7 | ||

| Other | < 0.8 |