Description

One of the comments, when customers start working with our standard SoliPaper ULS-grade, was that it was much stronger compared to standard high temperature fiber paper In some large volume gasket applications this high strength and density was not required which led to the development of the lower density, but more economical, SoliPaper LOWPAC.

Utilizing an optimized production process, we are able to create a product close dimension tolerances, exceptionally low dust, high handling strength, and improved thermal insulating performance. SoliPaper LOWPAC is particulary suited to all applications requiring further processing (laminated composites, die-cutting, rolling, folding).

As SoliPaper LOWPAC (like the normal SoliPaper ULS) is manufactured based on our SoliWool ULS, it also has a classification temperature of 2300°F and is recommended for use till 2000°F continuously.

SoliPaper LOWPAC is using organic binders which burn out on the first firing, starting at approximately 500°F.

All products in the SoliWool ULS fiber product range, like the SoliPaper LOWPAC, meet the requirements specified under NOTE Q of European Regulation 1272/2008. SoliPaper LOWPAC products are therefore exonerated from labelling requirements in Europe.

Next to the SoliPaper in the low bio persistence grade (LBP) we also offer a standard range of RCF(-Zr) Papers from 2300 to 2600°F and special paper grades using PCW fibers up till 2950°F.

Benefits

- Low shot technology

- Excellent insulation performance

- High handling strength and low dust

- Economical solution for high volume gasket cutting

- Exonerated of carcinogenic classification under Note Q

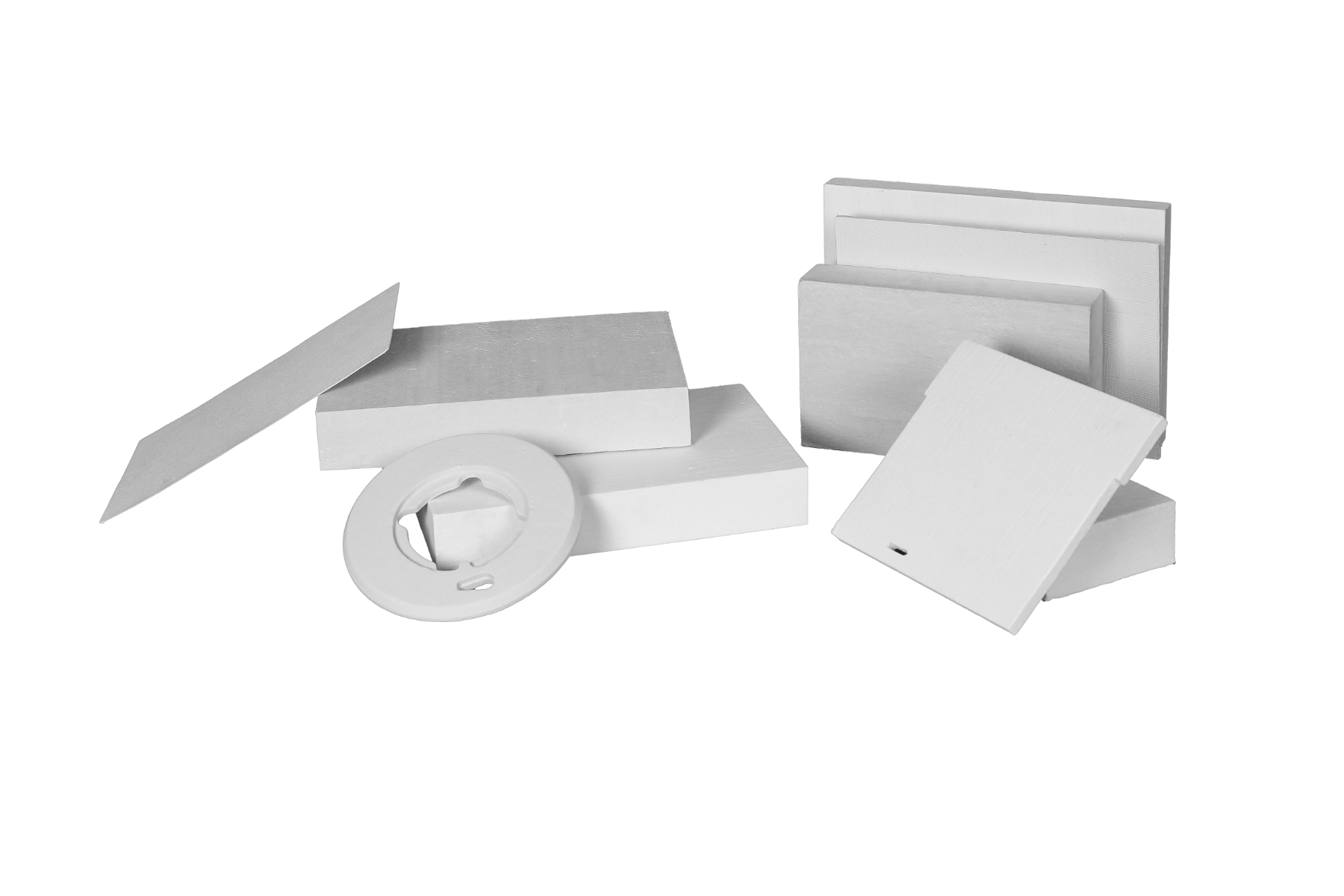

Typical applications

- Gaskets for domestic appliances and boilers

- Thermal insulation in automotive heat shields

- Non-ferrous molten metal handling

- General technical insulation of furnaces and technical installations

Type

Paper from Low Bio Persistence (LBP) high temperature insulation fiber.

Temperature range

SoliPaper LOWPAC has a classification temperature of 2300°F and advised for maximum continuous use at 2000°F.

The maximum continuous use temperature provided on the website is a guideline and only applicable in a clean oxidizing atmosphere.

Product range

SoliPaper LOWPAC is a spin-off of our standard SoliPaper ULS®, and part of an extensive product range supplied by Vulcor Insulation. Vulcor Insulation is supplying insulation solutions from cryogenic to high temperature applications. All products offered by Vulcor are manufactured in house or sourced from exclusive trusted 3rd party partners.

Technical support

Vulcor Insulation provides specifiers and customers with guidance on all aspects of the materials selection for their application, the installation and compliance with relevant regulations and performance standards.

For additional information about product performance, or to identify the recommended product for your application, please contact the team at Vulcor Insulation.

Availability

SoliPaper LOWPAC is manufactured in a density of 9.5 to 10.5 PCF and in a limited thickness range from 1/16 to 1/4 inch.

The jumborolls have a standard width of 47-1/4 inch which allow them to be loaded with 4 rolls per pallet. The jumborolls are provided with heist belts in the roll which allow swift loading on the feeder for high volume gasket cutting.

| Length (inch) | Width (inch) | Thickness (inch) |

|---|---|---|

| 9000 | 47-1/4 | 1/16 |

| 4500 | 47-1/4 | 1/8 |

| 2250 | 47-1/4 | 1/4 |

Properties

| Properties measured | Standard | Unit | SoliPaper LOWPAC |

|---|---|---|---|

| Grade | LBP | ||

| Colour | white | ||

| Classification temperature | °F | 2300 | |

| Continuous use temperature | °F | 2000 | |

| Density | kg/m3 | 150-170 | |

| Loss on ignition | wgt% | < 8 | |

| Tensile strength | |||

| Thickness 1/16 to 1/8 inch | PSI | > 45 | |

| Thickness 1/8 to 1/4 inch | PSI | > 75 | |

| Permanent linear shrinkage | EN 1094-7 | % | |

| @2200°F | < 2 | ||

| Thermal conductivity | ASTM C-201 | BTU·in/hr·ft2·°F | |

| @500°F | 0.42 | ||

| @1000°F | 0.68 | ||

| @1500°F | 1.14 | ||

| @1800°F | 1.46 | ||

| Chemical composition (after firing) | ISO 12677 | % | |

| SiO2 | 63-66 | ||

| CaO | 26-33 | ||

| MgO | 3-7 | ||

| Other | < 0,8 |