Description

SoliBlanket ULS-grade, as the name implies, is the original product developed to utilized the Ultra Low Shot fiber technology. As we believe that reducing energy consumption and minimizing CO2 emissions in the production process will become part of sustainable environmental drivers, thermal insulating properties will become more important. SoliBlanket ULS-grade, benchmarked against several other standard LBP blankets, resulted in thermal conductivities up to 44 % better than some Generation I products @ 1000°C. Another great benefit of the Ultra Low Shot technology used for manufacturing our SoliBlanket ULS-grade.

The key technical aspect of our Generation III, ULS technology, is to make products with less shot and a higher fiberindex. This results in a better blanket product. The Soliblanket ULS-grade is stronger, feels more comfortable to handle and provides better thermal insulation. During installation our ULS technology fiber products offers a higher resiliency after compression, which is particularly important when making fiber modules or in case the blanket (strip) is installed perpendicular to the main fiber orientation, or in easier words; stack(bonded).

All products in the SoliWool ULS fibers product range, like the SoliBlanket ULS, have been tested at the Fraunhofer institute and meet the requirements specified under NOTE Q of European Regulation 1272/2008. All SoliBlanket ULS fiber products are therefore exonerated from labelling requirements in Europe. Vulcor is REACH compliant and has completed Fraunhofer certification for the SoliBlanket ULS product range.

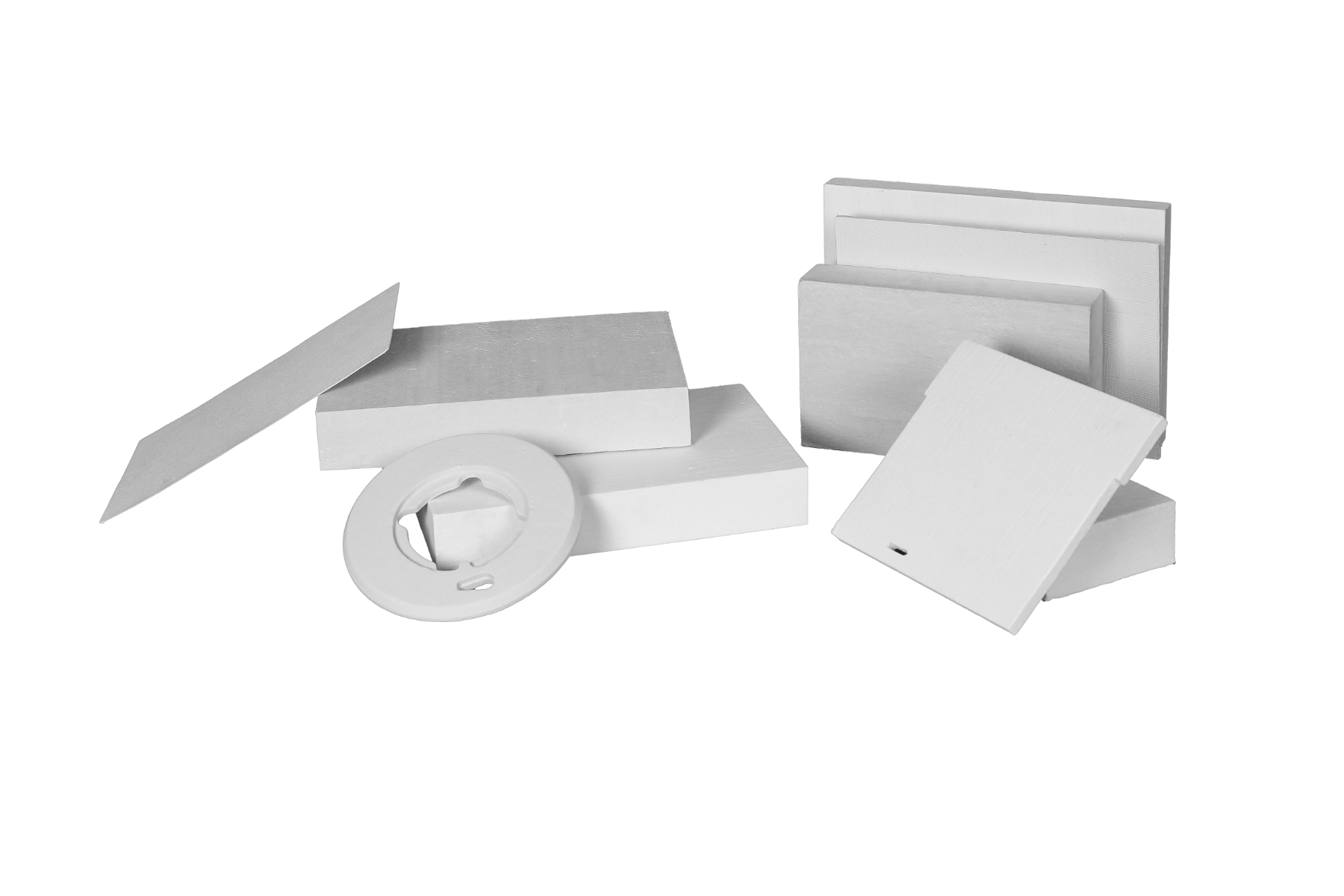

SoliBlanket ULS-grade is part of the SoliBlanket product range. With a variety of five Refractory Ceramic Fiber (RCF) grades and the famous ‘ULS’ Low Bio Persistence Fiber grade we are offering one of the most extensive ranges of high temperature fiber blankets in the market today. With our different chemical compositions we are able to provide a solution to nearly every atmosphere or temperature.

Benefits

- High fibre index

- Low shot technology

- Excellent insulation performance

- High handling strength

- Low heat storage

- Excellent thermal stability

- Exonerated of carcinogenic classification under Note Q

Typical applications

- Thermal insulation for furnace lining

- Thermal insulation for lining stacks and chimneys

- Thermal protection cover in aluminum industry

- HRSG thermal liner for boilers and ducting

- Exhaust heat shields for automotive application

- General technical insulation of furnaces and

technical installations.

Type

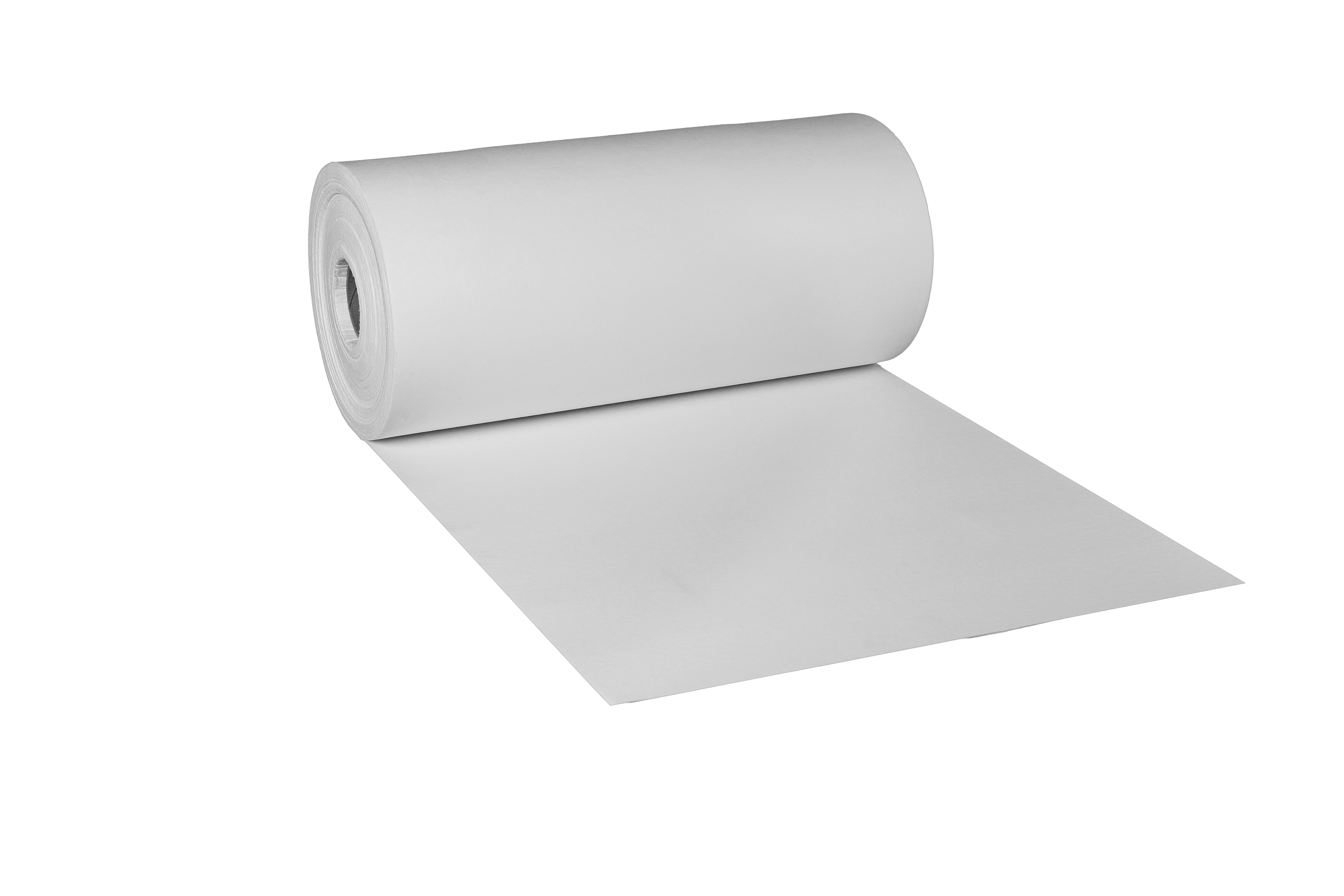

Blanket from Low Bio Persistence (LBP) fiber high temperature insulation wool.

Temperature range

SoliBlanket ULS-grade has a classification temperature of 1260°C and advised for maximum continuous use at 1100°C.

The maximum continuous use temperature provided on the website is a guideline and only applicable in a clean oxidizing atmosphere. We remind you that in stack bonded applications all low bio persistence fiber products tend to loose it reversibility or spring-back in long term applications over 900°C.

Product range

SoliBlanket is part of an extensive product range supplied by Vulcor Insulation. Vulcor Insulation is supplying insulation solutions from cryogenic to high temperature applications. All products offered by Vulcor are manufactured in house or sourced from exclusive trusted third party partners.

Technical support

Vulcor Insulation provides specifiers and customers with guidance on all aspects of the materials selection for their application, the installation and compliance with relevant regulations and performance standards.

For additional information about product performance, or to identify the recommended product for your application, please contact the team at Vulcor Insulation.

Availability

All SoliBlanket products from the Low Bio Persistence blanket range are available in densities from 64 to 160 kg/m3 and in a standard thickness range from 6 to 50 mm. As result of our high fiber index our thickness range in 160 kg/m3 is limited to 25 mm as our product becomes to strong to create a roll.

SoliBlanket is standard supplied in shrink wrap plastic film, and can be supplied in carton boxes (except 6 mm blanket which is only available with 4 rolls per carton box). The blankets in shrink wrap are placed on a heat treated export pallet with 24 rolls per pallet. Please refer to list below for availability of densities and dimensions.

| Length (mm) | Width (mm) | Thickness (mm) | 64 kg/m3 | 96 kg/m3 | 128 kg/m3 | 160 kg/m3 |

|---|---|---|---|---|---|---|

| 5500 | 610 | 6 | O | X | O | |

| 14640 | 610 | 13 | O | X | X | X |

| 9760 | 610 | 19 | O | O | O | O |

| 7320 | 610 | 25 | X | X | X | X |

| 4880 | 610 | 38 | X | X | X | |

| 3660 | 610 | 50 | X | X | X | |

| Standard item | X | |||||

| On request | O |

Properties

| Properties measured | Standard | Unit | SoliBlanket | ULS-grade | ||

|---|---|---|---|---|---|---|

| Grade | LBP | |||||

| Colour | white | |||||

| Classification temperature | °C | 1260 | ||||

| Continuous use temperature | °C | 1100 | ||||

| Density | kg/m3 | 64 | 96 | 128 | 160 | |

| Tensile strength | EN 1094-1 | kPa | 35 | 55 | 75 | 90 |

| Permanent linear shrinkage | EN 1094-7 | % | ||||

| @1200°C | < 1,5 | |||||

| Thermal conductivity | ASTM C201 | W/mK | ||||

| @200°C | 0,06 | 0,05 | 0,05 | 0,04 | ||

| @400°C | 0,10 | 0,09 | 0,08 | 0,07 | ||

| @600°C | 0,16 | 0,14 | 0,12 | 0,11 | ||

| @800°C | 0,26 | 0,21 | 0,18 | 0,17 | ||

| @1000°C | 0,38 | 0,28 | 0,25 | 0,23 | ||

| Chemical composition | ISO 12677 | % | ||||

| SiO2 | 63-66 | |||||

| CaO | 26-33 | |||||

| MgO | 3-7 | |||||

| Other | < 0,8 |