Description

SoliBoard HS ZR-grade is the High Strength version of our highest temperature performing RCF board, the SoliBoard ZR-grade. With a typical density of 450 kg/m3, using the benefits of our Generation III, Ultra Low Shot fiber technology and advanced engineering, the SoliBoard HS ZR-grade is providing a solution in applications where standard boards would not be acceptable from a strength and handling perspective.

SoliBoard HS ZR-grade is manufactured on our continuous board line which has a total length of approximately 300 meter and a production width of 1200 mm. This line was set up in 2019, and is not only fully PLC controlled, but also equipped with robots to minimize manual labor. Our board line is equipped with the latest drying techniques, and is enabling double side surface treatment. This allows us to not only secure the highest quality, but also allows us to be competitive at high output.

Next to that we utilize a highly efficient drying technique which does not only reduced our energy consumption with 50 % compared to conventional forced air drying, but also allows us to manufacture uniform, lightweight, low shot and stable board up to a thickness of 100 mm at high consistency, quality and performance. In a world where reducing energy consumption and minimizing CO2 emissions is part of sustainable environmental drivers, it is good to realise that we have already taken the first step.

SoliBoard HS ZR-grade is taking great benefit of the advanced Ultra Low Shot spining technology, which is commonly used for the production of our fiber products. SoliBoard is produced with a very tight thickness tolerance and offer unparalleled flatness.

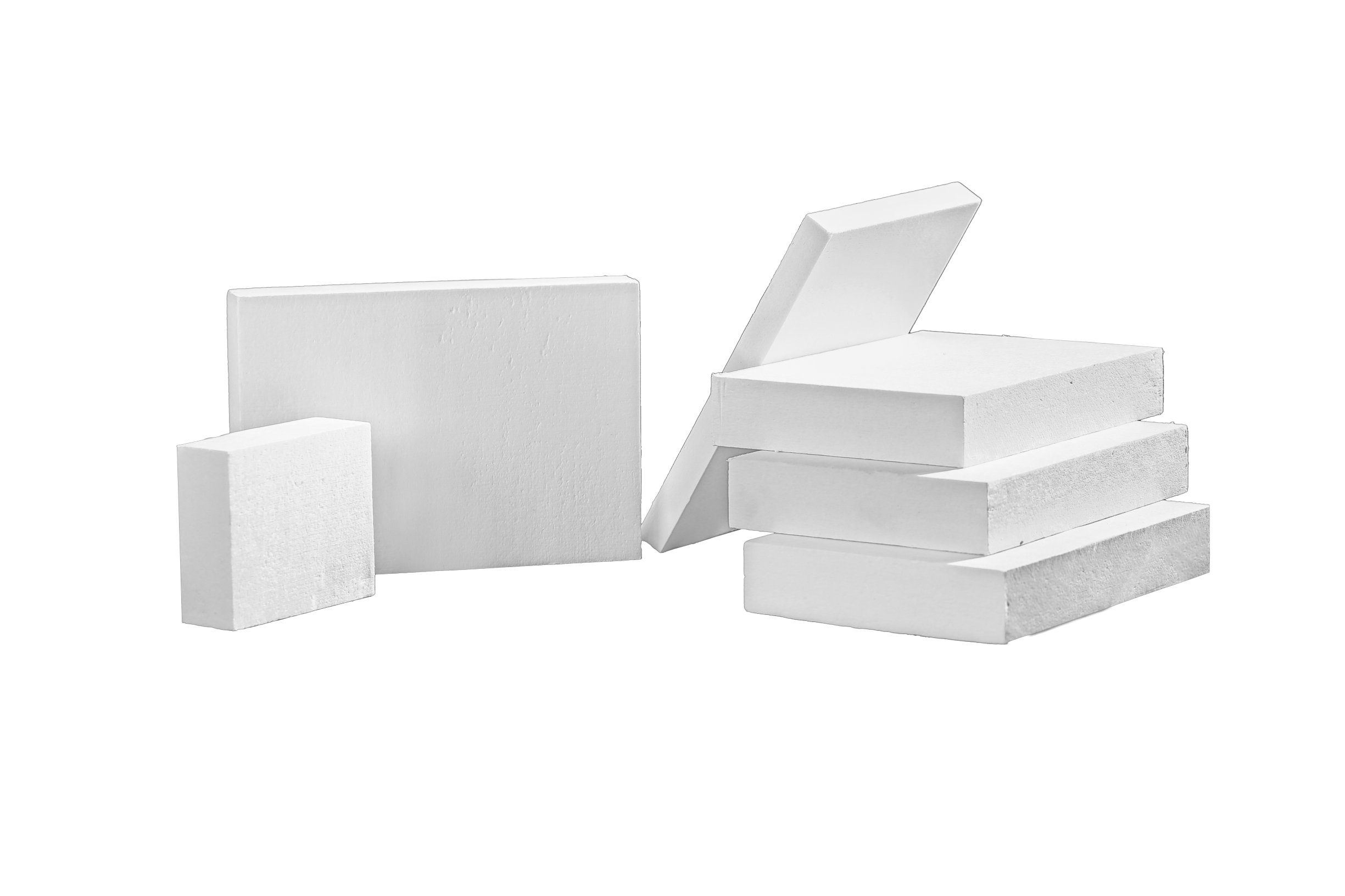

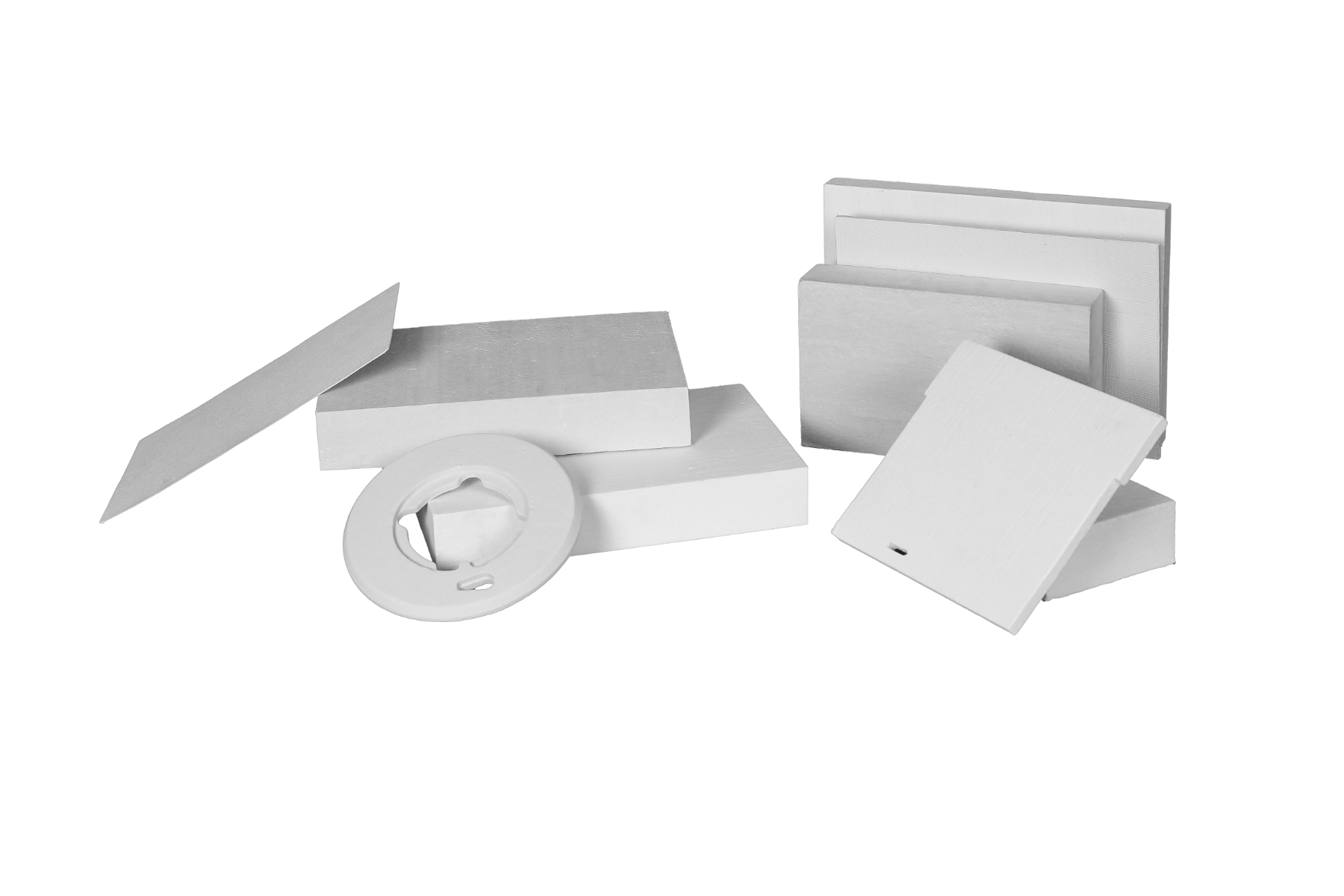

Vulcor is offering one of the most extensive product ranges in high temperature board products. We offer a complete series of standard boards, a high strength series which is both offering higher green strength as better strengh after first firing, and a high temp series which are manufactured from mixed fiber chemistries (typically using very high temperature resistant PCW fibers) for the most demanding applications.

Benefits

- Low shot technology

- Excellent insulation performance

- High handling strength

- Resistant to erosion from high gas velocities

- Can be used in direct flame contact

- Low shrinkage

- Excellent thermal stability

- Resistant to thermal shock

Typical applications

- Thermal insulation for furnace linings

- High temperature back-up insulation for ladles and torpedo cars

- Tundish and launder covers in the casting of various alloys

- Back-up insulation in melting furnaces and

protection of burners for the glass industry - Lining combustion chamber for gas fired boilers and heaters

- General technical insulation of furnaces and

technical installations

Type

High Strength Boards from high temperature Refractory Ceramic Fiber (RCF) insulation wool and selected fillers.

Temperature range

SoliBoard HS ZR-grade has a classification temperature of 1430°C (2600°F) and advised for maximum continuous use at 1260°C (2300°F).

The maximum continuous use temperature provided on the website is a guideline and only applicable in a clean oxidizing atmosphere.

Product range

SoliBoard is part of an extensive product range supplied by Vulcor Insulation. Vulcor Insulation is supplying insulation solutions from cryogenic to high temperature applications. All products offered by Vulcor are manufactured in house or sourced from exclusive trusted third party partners.

Technical support

Vulcor Insulation provides specifiers and customers with guidance on all aspects of the materials selection for their application, the installation and compliance with relevant regulations and performance standards.

For additional information about product performance, or to identify the recommended product for your application, please contact the team at Vulcor Insulation.

Availability

SoliBoard HS ZR-grade is manufactured in a density of 420 to 480 kg/m3 and in a standard thickness range from 10 till 50 mm.

SoliBoard is available in the standard dimensions 1200×1000 mm which are supplied on carton boxes of approximately 120mm high (based on the thickness of the board). Please refer to the list below for packaging details of the SoliBoard product range, other sizes are available on request.

1200 x 1000 mm

| Thickness | Per carton box | Boards per pallet |

|---|---|---|

| 10 | 12 | 168 |

| 13 | 10 | 140 |

| 15 | 8 | 112 |

| 20 | 6 | 90 |

| 25 | 5 | 70 |

| 40 | 3 | 45 |

| 50 | 2 | 36 |

In the North American market we are supplying our SoliBoard in a standard dimension of 47 1/4×36 inch and from 3/8 up till 2 inch thick.

47 1/4 x 36 inch

| Thickness | Per carton box | Boards per pallet |

|---|---|---|

| 3/8 | 12 | 168 |

| 1/2 | 10 | 140 |

| 1 | 8 | 112 |

| 1 1/2 | 6 | 90 |

| 2 | 5 | 70 |

Properties

| Properties measured | Standard | Unit | SoliBoard HS X-grade | SoliBoard HS ZR-grade |

|---|---|---|---|---|

| Grade | RCF | RCF | ||

| Colour | White / tan | White / tan | ||

| Classification temperature | ℃ | 1260 | 1430 | |

| Continuous use temperature | ℃ | 1150 | 1250 | |

| Density | kg/m3 | 420-480 | 420-480 | |

| Modules of Ruprutre | EN 993-6 | |||

| Unfired | kPa | ≥ 1300 | ≥ 1300 | |

| Fired for 24h @ continuous use temp | kPa | ≥ 400 | ≥ 400 | |

| Compressive strength (unfired) | EN-ISO8895 | |||

| @ 5% deformation | kPa | ≥ 400 | ≥ 400 | |

| @10 % deformation | kPa | ≥ 500 | ≥ 500 | |

| Loss on ignition | GB/T 6900 | wgt% | < 6 | < 6 |

| Permanent linear shrinkage | EN 1094-7 | % | ||

| @1200℃ | < 3 | |||

| @1300℃ | ||||

| @1400℃ | < 4 | |||

| Thermal conductivity | ASTM C201 | W/mk | ||

| @200℃ | 0,06 | 0,07 | ||

| @400℃ | 0,08 | 0,09 | ||

| @600℃ | 0,12 | 0,13 | ||

| @800℃ | 0,16 | 0,17 | ||

| @1000℃ | 0,21 | 0,22 |